All too often Coaxial cables are stressed to their limit, mechanically as well as physically, and sometimes even beyond it because of the way they are constructed: whenever they are subjected to high tensile and torsional loads - which is the case if they are used on sewer inspection robots - the central coaxial conductor located at the core experiences the full brunt of these forces, thereby becoming the weakest link in the package. If there is an accident, the heavy TV inspection robot is pulled back out of the sewer by the cable. Core breakages inside of the cable are then really only a question of time. In the case of Hradil’s New Generation Twisted-Pair Cable with its 7.4 mm diameter, however, all tensile and torsional loads are absorbed by the complete cable cross-section. Apart from its outstanding mechanical properties, the New Generation Twisted-Pair Cable has excellent EMI characteristics. Moreover, and, different from the Coax cable, there are no limitations for the Twisted-Pair Cable in terms of available lengths and no data loss. HRADIL offers the New Generation Twisted-Pair Cables with lengths of 100 to 750 meters, and, if requested, even as a plug-and-play version with the connector already fitted.

Author: Alfred F. Hradil, Managing Director of Hradil Spezialkabel GmbH

When performing sewer inspection work, coaxial cables are usually used to transmit the camera signals. This exposes them to very high mechanical loads, and not only because sometimes brute force is applied to pull the cables around corners or protruding edges. If the heavy robot has an accident it is pulled back out of the sewer by its „tail“, i.e. the cable. The mechanical forces can inflict severe damage on coaxial cables, as these forces act directly on its central coaxial conductor - core fracture or core damage is then only a matter of time. Or, in other words, users are advised to keep a replacement cable handy.

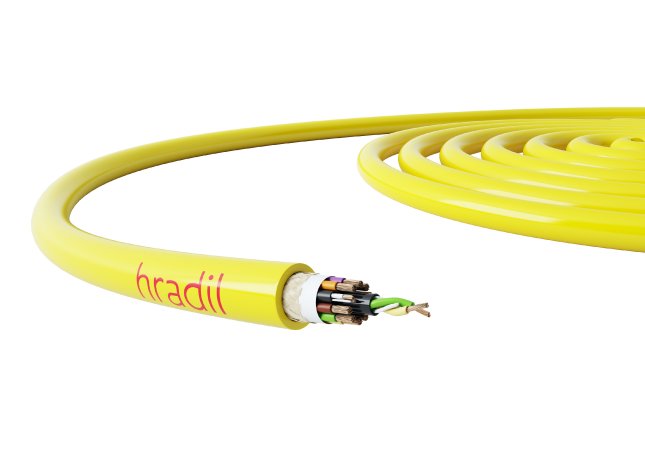

The New Generation Twisted-Pair Cable shows HRADIL Special Cables exploring new ground. Field use has proven that is has a signifiantly longer product life.

The explanation for the high mechanical robustness of the New Generation Twisted-Pair Cable is the way it has been designed: it absorbs the tensile and torsional forces, evenly distributing them across all the different construction elements it comprises. Its tensile strength exceeds 2,500N, its bending radius 80mm. Apart from the fact that it is stranded free from strain with a fixed lay length, it also features an open braided shield made with high-strength textile yarn which is embedded into the PUR cable jacket. In the double-layered Twisted-Pair Cable with 9x0.5mm², 2x0.09mm² and 2x0.15mm², each of the layers are separated from each other by a special non-woven fabric to ensure smooth slide properties. HRADIL’s New Twisted-Pair Cable is low-adhesion and resistant to hydrolysis, oil, UV radiation and microbes.