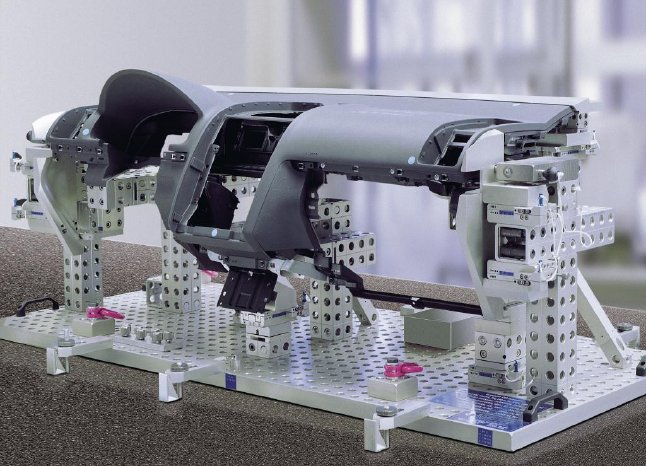

In order to achieve meaningful measuring results on accuracy, parts are mounted for dimensional measuring on special fixtures. Custom built fixtures guarantee optimal access to the measuring points.

With modular fixturing systems such as Alufix it is possible to assemble custom-built fixtures on the spot without any lead time. Changes in part design can be catered for immediately due to the modularity of the system. Usually just a few manual operations are necessary to adapt a fixture to the latest part data. The Alufix system consists of a variety of highly accurately manufactured high-tensile aluminum components, which can be used over many years without any loss of quality. The part variety and multiple application possibilities of individual components enable diverse assembly variations. Through bores in Alufix bars allow different arrangements using integrated connection technology. Since the Alufix components are manufactured in high-tensile aircraft aluminum, the assembled fixtures are not only stable but also comparatively light.

After use fixtures are disassembled and individual components are available for new applications. The system comes in different sizes, which are inter-combinable.

Plastic parts require special treatment during positioning as materials are often relatively soft and parts unstable. In order to avoid deformation the parts should not be clamped, but gently fixed without exerting any pressure on the part. Temporary deformation would lead to falsification of measuring results. Alufix fixtures are conceived in such a way that parts are held securely but without tension.

When individual plastic components are to be checked without using measuring instruments, gauges are a good option. They are useful for checking that assembly or connection dimensions are within given tolerances. With conventional gauges however no statement about the extent of deviation is possible. A more sophisticated type of gauge manufactured by Witte Bleckede can be equipped with dial indicators offering a reading on the measure of deviation. Gauges are frequently used parallel to series manufacturing to check plastic covers of passenger car instrument panels. Since the gauges from Witte are manufactured in high-tensile, anodized aluminum, they combine low wear with easy handling.