Converting sunlight into electricity is a future market with tremendous growth potential. According to a study by the European Commission's DG Joint Research Centre, great progress has been achieved in the spread of photovoltaics, especially in Europe, with an estimated installation of approximately 14 gigawatts (GW). By 2020, installed PV capacity in Europe is projected to reach 100 GW. With its customer-oriented products, Heraeus helps increase the efficiency of solar cells and simplify and accelerate their manufacture.

Silver conductive pastes for more efficient solar cells

Silver, in the form of conductive pastes, plays an important role in the electronics and photovoltaics industries. These include silver-based pastes for manufacturing very delicate, high-conductivity contact paths on solar cells, which reduce line and contact resistance while minimizing shadowing of the solar cells and electrical resistance. Heraeus is constantly developing new formulations to offer customers innovative technology solutions. The latest generations of paste demand high efficiency with low consumption and silver content.

The metallization pastes introduced in 2011, SOL 9410/9411, enable the production of highly efficient crystalline solar cells and are optimized for production with high throughput and low cost. They help achieve an excellent aspect ratio, meaning an optimized ratio of width to height for the fine conducting paths. The new SOL 200 series of pastes is designed for the back-side contacts of crystalline solar cells. Their reduced silver content and low consumption lowers acquisition and production costs for customers. All Heraeus pastes are cadmium-free to improve environmental friendliness.

The outstanding technical performance of Heraeus' metallization pastes makes it one of the top suppliers in this field. The permanent expansion of production capacity for silver pastes at facilities in the United States, Asia, and Germany is aimed at maintaining this position.

Ultra-thin layers on solar cells

Thin-film solar cells are gaining importance as an alternative to silicon solar cells. Through the use of thin-film technology, a fine semi-conductive layer is deposited onto a substrate, which typically consists of glass, metal, or plastic. The semi-conductive layer can be composed, for example, of amorphous silicon, cadmium telluride, or copper-indium-gallium-diselenide (CIGS). The semiconductor layer in this manufacturing technology is a mere thousandth of a millimeter thick, thus thin-film cells are 100 times thinner than crystalline solar cells and require significantly less material.

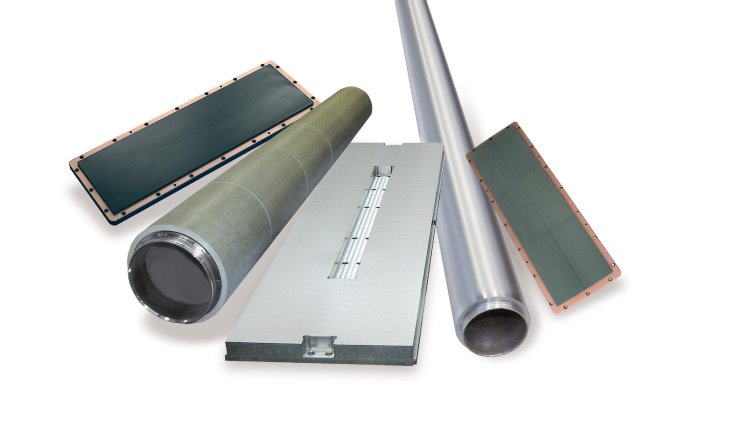

Sputtering is a key technology for the production of thin layers. In solar cell production, this technique is used to create many layers: semi-conductive and conductive layers for front-and back-side contacts. The source of material for these layers is the sputtering target. During sputtering, the inert gas argon is fired at the targets in a vacuum chamber charged with electrical voltage. The positively charged gas ions knock individual atoms out of the surface of the target, which then condense on the substrate material as an extremely thin coating. Heraeus has developed a variety of sputtering targets for all current types of solar cells. The quality and purity of the sputtering targets impact the solar cell's functional efficiency and performance.

Specialty emitters from UV to infrared make solar cells more efficient

Solar cells and modules have to be tested to check production quality, characterize the cells, and assign them to performance categories. Only perfectly matched cells are ultimately combined into one module, which requires reliable and reproducible light sources that mimic the full spectrum of the sun's light rays as closely as possible. Xenon flash lamps-from small and circular to linear and up to two meters long-accomplish this.

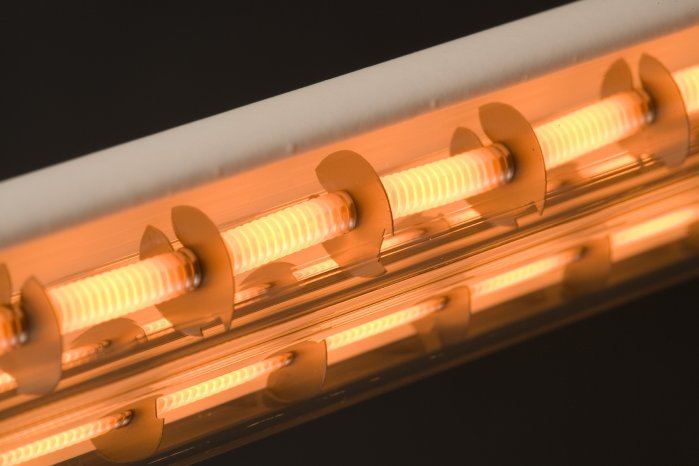

Infrared emitters are part of a project sponsored by the German Federal Ministry of Education and Research. Four partners are working on system designs with the aim of researching a new manufacturing process for CIGS semiconductor layers that will attain the highest levels of module efficiency.

The partner for heating technology is the specialty light sources business group (Heraeus Noblelight), which has decades of experience in infrared heating technology. Typically, the manufacture of solar cells uses QRC infrared emitters with nano reflectors, which perform their tasks in a vacuum or under high-temperature conditions in a particularly stable and energy efficient manner.

Solar cells need high-tech material quartz glass

Quartz glass has become essential for high-temperature applications in photovoltaics: Its resistance to thermal shock, high chemical purity, and resistance to corrosion make this high-tech material irreplaceable. Quartz crucibles from Heraeus are used in the first manufacturing step for traditional solar cells: For monocrystalline wafers, a silicon monocrystal is drawn from a 1400°C silicon melt into a quartz glass crucible. Quartz components are used in wafer-based cell manufacturing both for the industrial production of solar silicon as well as the processing of silicon wafers into solar cells. Typical products include quartz glass boats, which are used as wafer carriers in high-temperature processes. Solar panels manufactured using thin-film technology also rely on components made of quartz glass.

Note about PVSEC presentation: Dr. Martin Schlott, Head of Development in the Thin Film Materials Division at Heraeus, will be speaking at the PVSEC conference on Wednesday, September 7, on the topic of highly efficient tube targets for the production of CIGS thin-film solar cells.

Heraeus provides detailed information about its contribution to the photovoltaics industry at www.heraeus-photovoltaics.com.