Outstanding teamwork appreciated

The award winners and their teams were recognized at a ceremony by the Heraeus Board of Management, CEO Jan Rinnert and COO Rolf Najork. Both commended the 16 projects submitted by Heraeus developers and appreciated the outstanding teamwork of this year's finalists for the Innovation Award. "The teams that are successful are always those in which different competencies are joined together, creating a critical atmosphere for innovation. This diversity is a catalyst for innovation", said Jan Rinnert, Chairman of the Board of Management at Heraeus Holding. And Rolf Najork, Member of the Board of Management at Heraeus, stressed: "Teamwork - using knowledge about the common market and collective technical abilities - is the primary key to success, in order to perform at the highest level". Nearly 250 product innovations have been submitted since the first competition of the Innovation Award in 2003, and a total of 40 products and processes have been honored.

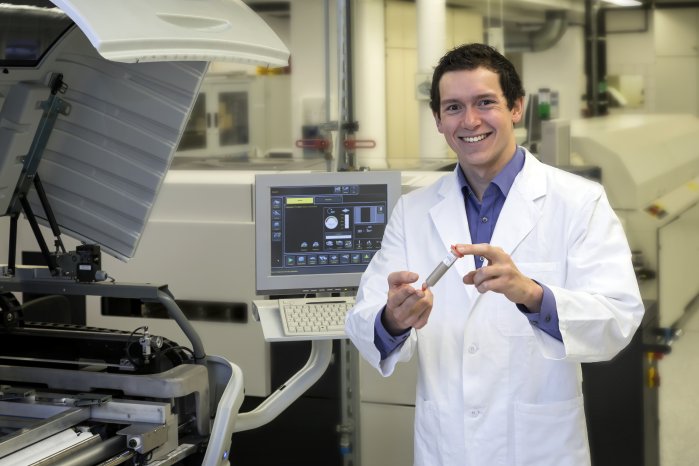

Best Product Innovation:

New conductive adhesives with reduced silver content

(Daniel Hanselmann and team, Heraeus Materials Technology)

Conductive adhesives containing silver connect electronic and electrical components in electrical circuits, semiconductor components, smart cards, displays, and sensors. Conventional adhesives require a silver content of more than 70 percent by weight to maintain their electrical conductivity. If an adhesive contains too few silver particles, they can no longer touch each other, and the electrical connection is interrupted. Conductive adhesives play a critical role in electronics, but because of cost pressure, the number of competing technologies is steadily growing. Conductive adhesives with a significantly lower silver content are countering this trend. Daniel Hanselmann and his team have now developed a cost-effective alternative. Their innovation replaces the conventional spherical silver particles in the adhesive with lamellar conductive silver particles. These silver flakes are supported and aligned by a scaffolding of less expensive spherical filling materials. "With this geometrical 'trick,' we were able to reduce the adhesive's silver content to less than 40 percent by weight without impairing its reliability and electrical properties," says Daniel Hanselmann, describing the cost-effective mixture of conductive and nonconductive particles.

Best Process Innovation:

Innovative dissolving process for catalysts containing palladium

(Dr. Christoph Röhlich and team, Heraeus Precious Metals)

Monoethylene glycol (MEG) is a key component in a number of important modern materials, such as polyester and PET. More than 20 million tons of MEG are used each year around the world. In China alone, demand is rising by 7% annually. One source of raw materials for MEG is the coal deposits there. The conversion of coal to MEG involves using catalysts containing palladium. The introduction of this process in China has generated large quantities of spent catalysts, which can be recycled. Dr. Christoph Röhlich and his team have now developed an innovative recycling method that involves a series of processing steps to separate the palladium from the catalyst carrier, attaining nearly 100 percent recovery of the precious metal. Important side effect: In the standard process, the catalyst is melted at more than 1200°C, which destroys the catalyst carrier. Not so in the innovative recycling method. "The spherical catalyst carrier is retained intact, freed of all foreign substances, and can be dried and then reused for the production of new catalysts," says Christoph Röhlich, describing the nearly complete "recycling" of the spent catalyst.

2nd place Product Innovation:

Innovative materials for OLED lamps

(Dr. Armin Sautter and team, Heraeus Precious Metals)

Organic light-emitting diodes (OLEDs) are the lighting technology of the future. OLED lamps are highly efficient and provide a pleasant light. An OLED consists of a very thin layered structure just 200 to 500 nanometers thick. As a result, they can be fabricated as transparent displays on flexible substrates, curved and shaped, thereby giving designers of lamps and lighting concepts a great deal of freedom. Despite their many advantages, these lamps are still too expensive to penetrate the mass market. Dr. Armin Sautter and his team have now achieved a breakthrough by developing a new material for producing these thin layers. For a key functional layer on the OLED, the team uses a conductive polymer that can be applied as a thin layer by printing and coating processes, forming transparent conductive films. "Unlike previous materials, our product can perform two essential functions of the OLED in a single layer: the injection of positive charge carriers and the function of the transparent electrodes. This means that a large area can be covered at a significantly lower cost, while eliminating process steps and increasing throughput," says Dr. Armin Sautter. The combination of this conductive polymer with a printed silver-metal mesh will significantly reduce the cost of producing OLEDs.

3rd place Product Innovation:

Production of a temperature-resistant platinum-siloxane catalyst

(Jörg Fuchs Alameda and team, Heraeus Precious Metals)

Labels, medical tubes, casting compounds, baby pacifiers, adhesive bandages, electronic components, and special paper coatings all have one thing in common: They contain silicones. High-quality silicones are produced from polysiloxanes using platinum-siloxane catalysts. Heraeus is the leading supplier of these special homogeneous catalysts, which must constantly be adapted to meet the market's evolving demands. In order to coat paper with a thin layer of silicone, a major Chinese supplier to label manufacturers required a highly temperature-resistant catalyst with good storage stability and processability even at high ambient temperatures. Problem: The standard colorless catalyst slowly decomposes at higher temperatures. A Heraeus team of German and Chinese developers has now come up with a stable variation of the organometallic platinum-siloxane catalyst. "The breakthrough involved adding a precisely measured quantity of a stabilizer. In a complicated procedure, we were able to identify the optimal balance between stability and reactivity for the catalyst," explains Jörg Fuchs Alameda of Heraeus Precious Metals. The new laboratory synthesis was successfully taken to production scale at Heraeus Shanghai. This key project has made Heraeus the first international supplier of platinum-siloxane catalysts as well as the market leader in China.