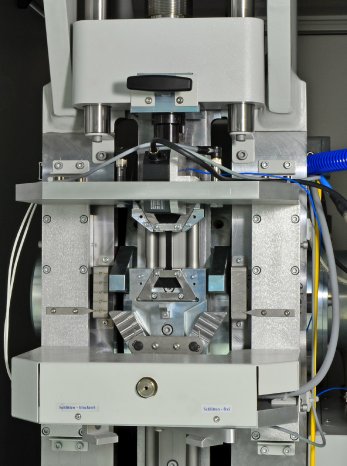

In the developed rotational impact tester, a 300 kg rotating flywheel mass takes over the speed preselection and energy storage. However, other rotating masses can also be realized. For the actual test, the energy is transferred to a linear slide with the integrated specimen holder. The actual tensile test then takes only a few milliseconds. Compared to other technologies, with which equally dynamic tests are carried out (like pendulum impact testers, drop testers or high-speed testing machines), the rotational impact tester stands out due to its high testing speed and its high impact energy, at a comparatively small machine size.

The prototype is currently already being used for materials testing at the Chemnitz University of Technology. We are happy to offer demonstrations and preliminary tests. For further information contact us at the telephone number +49 35242 4450 or write us an e-mail: info@hegewald-peschke.de.