The MEC® III electronic weigher not only has contributed to the success of the ROTO-PACKER®, but has also written a success story of its own. Since its approval in 2003, 10,000 electronic weighing systems have been sold worldwide, 5000 units in the past two and half years alone.

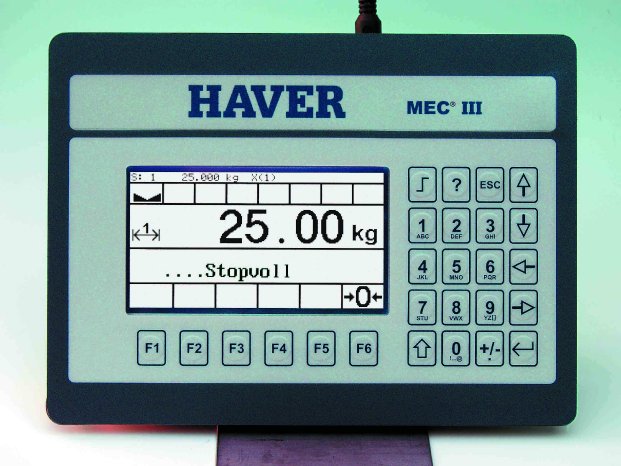

The MEC® III is not only a weigher, but at the same time it is also control system. It has a double function: Firstly it is responsible for recording the weight and controlling the weightdependent material flow in the filling spouts and secondly, it also takes over control work such as valve bag closing and the discharge from the packing machine. The MEC® III is the first selfactuating weigher with a European design approval, which HAVER & BOECKER received in 2007. The graphic operator panel enables a dialogue with the machine operator in almost every national language. Because of its Ethernet capability, the filling spouts can also be operated externally. This userfriendly concept makes the MEC® III accessible for remote diagnostics and software downloads via the internet. A quality assurance conforming operational data recording is also possible with the MEC® III network, which makes manual checks and records redundant. The MEC® III measurement system enables a maximum weighing range resolution of 6000 parts. That's a top value for the sector of selfactuating weighers for filling.

The Europeanwide MID approval (MID = European Measurement Instrument Directive) and many other design approvals outside of Europe make HAVER & BOECKER with its MEC® III an ambitious specialist of electronic weighing. PCsupported operating and service tools have also been developed for the MEC® III, which serve to simplify handling during operation and startups. The weigher electronics undergo strict quality tests on a regular basis within the scope of MID approval, thus assuring quality at the highest levels and assuring that customers receive nothing but premium quality products from HAVER & BOECKER.