HARTING Technology Group is currently exploring this research topic - among others - in the joint project dubbed "FlexiMon - Flexible Assembly Concept, which employs autonomous mechatronic manufacturing components. The project is part of the leading-edge cluster "It's OWL", which is being carried out as part of the "Leading-edge Cluster Competition" of the Federal Ministry of Education and Research (BMBF) within the framework of the High-Tech Strategy 2020 for Germany.

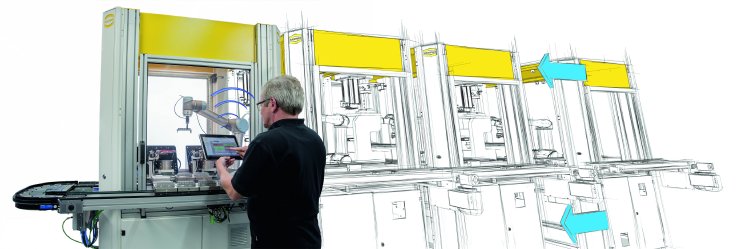

The launch point is the development of a modular production platform, which will be unveiled at the Hannover Messe 2014 trade fair and will feature - for the first time - the interplay of several production islands. The core of this platform is made up of configurable autonomous manufacturing modules equipped with "Plug and Produce" capabilities, autonomous control and a central, modular-independent man-machine interface.

HARTING Technology Group will use the Hannover Messe (April 7-11, 2014) trade fair to premiere three modules which handle the processes of screwing, stamping and inspecting. It is essential that these modules be adaptable during the production process so that e.g. changes in a work plan for the manufacture of a product can be directly implemented at the production level with no additional intervention.

In future, the modules are slated to offer human-machine-interaction in order to implement assistance functions that are intended to increase flexibility and configuration in a personalized, efficient form. Here, the idea is for flexible mechatronic components to be combined more dynamically on production lines without the need for manual on-site programming. In addition, the direct integration of system users means their knowledge and requirements can be taken into account via machine learning functions.