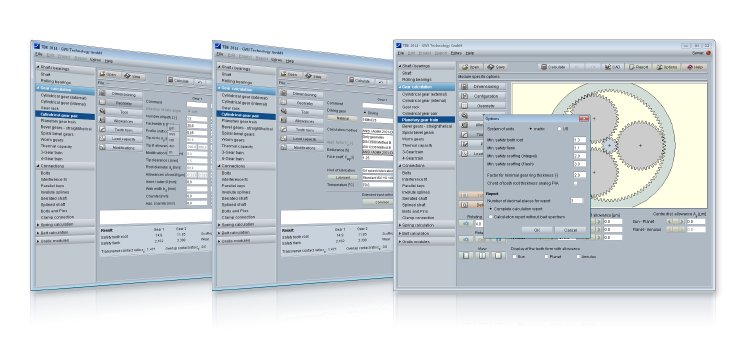

The new and updated version V31 comes with some interesting features. The calculation modules "Cylindrical gears" and "Planetary gear trains" allow the users to use the DIN 58405 standard for fine mechanics as well as ISO 1328 and ANSI/AGMA 2015 in addition to the DIN 3961 standard for gear allowances. Both modules now support not only DIN 3990 and ISO 6336, but also ANSI/AGMA 2101-D04 in order to determine the load capacity. Profile modifications, for example tip relief, are taken into consideration, in particular for scuffing. Furthermore, the cylindrical gear pair module allows users to define the number of tooth meshes. This can then be considered in the calculation of the load spectrum, too.

A new input option for the centre distance was also added to the dimensioning function dialog. The calculation module for planetary gear trains also features a new dimensioning function. In addition, the number of teeth of the planets can be automatically determined or defined individually.

All modules provide a new function for changing Metric and US Imperial units in the setting menu. The unit can be also changed by clicking the label element of the input field. All settings will be saved to the calculation file. The direct entry of the influence factor of surface hardening KV and the material treatment for every single notch effect is supported in the shaft module. This means that the consideration of different heat and surface treatments section-by-section is more user-friendly. Furthermore, the bearing calculation module provides various product lines of ABEG® bearings.

For more information, please contact GWJ by telephone +49 (0) 531 / 129 399-0 or email info@gwj.de or visit our webpage www.gwj.de.