In the past, the previous cutting technology relied on the force control principle. The force impacting the glass was set one single time; changes in cutting force through unavoidable deviations of surface quality, such as waviness or bending strength could not be detected and readjusted.

Now, the new cutting tool with integrated force sensor provides feedback for the cutting force applied to the glass and the new Cutting Force Controller CFC-250mag instantly intervenes to adapt the cutting force. "Especially in the case of thin glass, the cutting quality can be significantly improved", says Markus Gruber, VP Sales Glass at Grenzebach.

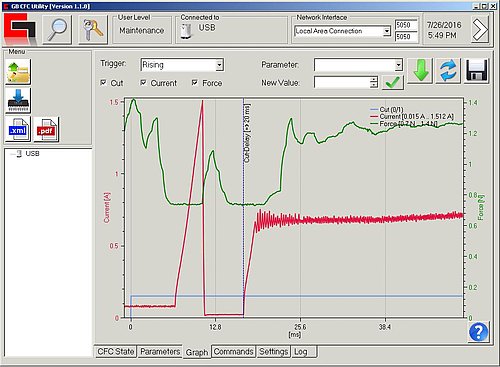

The new CFC-250mag cutting force controller developed by Grenzebach analyses, regulates and stabilizes the cutting forces measured in the cutting tool. Markus Gruber: "The significantly improved cutting quality means less glass loss due to bad snapping or bad edge quality."

Relevant process data can be directly detected and transmitted to an overriding system for further evaluation. Via the integrated interface, the CFC-250mag can be connected to the equipment network. The cutting force controller provides diagnostic capability via remote control and allows communication with other participants in the equipment network.

The modular design enables existing equipment upgrading to the new generation cutting technology. Concurrent use of both variants is feasible as well.

The relevant process data (e.g. cutting force actual values) is recorded and can be transmitted to a higher-level system for subsequent evaluation.

Length- and cross-wise cutting systems rely on field-tested Grenzebach cutting heads. The electromagnetic cutting force controllers allow accurate cutting force regulation. The developed new closed-loop controller makes the process even more accurate.