This unique and innovative approach replaces traditional volume gauging methods (i.e., fluids, pressurized air, and acoustics) with a fully automated, non-contact 3D solution.

“Converting a manual process to a non-contact, automated solution using 3D technology enables engine block manufacturers to achieve higher accuracy and repeatability than ever before,” says Terry Arden, CEO, LMI Technologies. “We see many opportunities like this in various markets where critical tolerances are being verified with manual approaches but are better achieved with 3D inspection.”

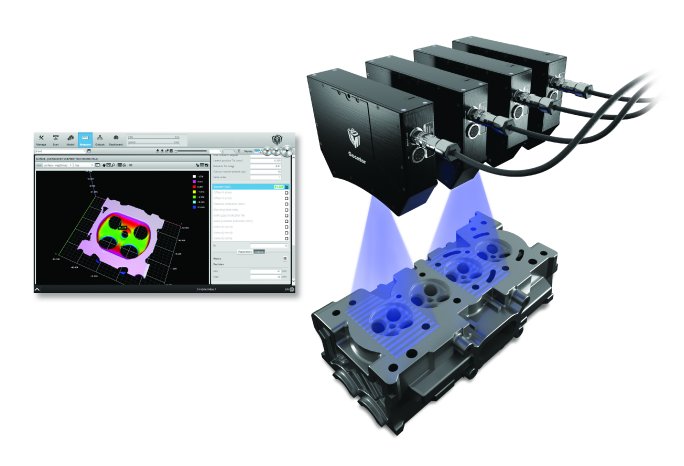

Gocator Volume Checker solves this application by combining the Gocator 3210 snapshot sensor (35 µm resolution) with custom built-in measurement tools to calculate the volume of engine cylinder heads and piston bowls.

The solution uses blue LED structured light to take a single snapshot scan and deliver measurement results at ± 0.04cm3 accuracy. This measurement occurs in a cycle time of less than 5 seconds––even on combustion chambers and pistons with highly-reflective surfaces. Traditional contact-based methods can take up to 5 minutes.

“The Gocator Volume Checker demonstrates the flexibility of our hardware and software platform, where we’re able to customize standard products with specific measurement tools to solve unique applications in many industries,” says Arden. “The approach we offer is a powerful blend of 3D scanning technologies married to innovative 3D feature measurement algorithms for breakthrough solutions”.

The Gocator 3210 snapshot sensor is IP67-rated and interfaces seamlessly to send pass/fail decisions to PLCs.

Gocator Volume Checker is now available for order. Contact sales@lmi3d.com.