The VW engine named EA211 evo has been equipped with the latest technologies to increase efficiency and is also available for natural gas models and plug-in hybrids. It thus plays a strategically important role worldwide in the further development of conventional drives and is one of the most efficient engines on the market. The coating of the cylinder liner is one of the important levers. VW will now install the corresponding production lines in China. For these lines, Gehring received the order to supply the laser roughening and honing machines. Dr. Sebastian Schöning, CEO of the Gehring Group, sees the development strategy confirmed: „We are happy that we were able to achieve concrete environmental improvements together with our customers.”

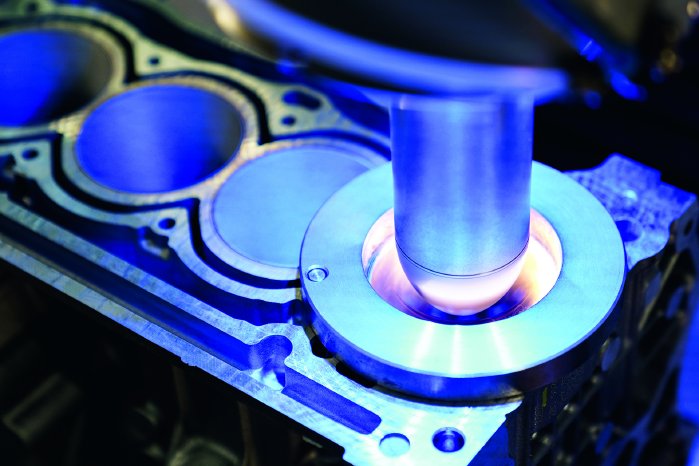

The thermal coating of cylinder bores is a highly sought-after technology for increasing the efficiency of internal combustion engines. Gehring is focusing on optimizing the process chain laser roughening - coating - honing. In order to produce a strong bond between the coating and the engine block, efficient roughening processes are required to ensure overall functionality. Gehring's laser roughening technology brings operative advantages. Apart from cost savings and an improved working environment, there is also a positive effect on the overall engine design. In addition to high adhesive tensile strengths with low roughness, economic advantages take effect in mass production, since no wearing tools are needed and coating material is saved. Both aluminum and cast iron can be pre-machined with the laser refining process. The Gehring laser roughening machines have two spindles with innovative rotation optics for the simultaneous machining of two cylinder liners. The coordinated process steps roughening - coating - honing lead to low-friction and wear-resistant cylinder liners, which contribute to more compact and more efficient internal combustion engines.