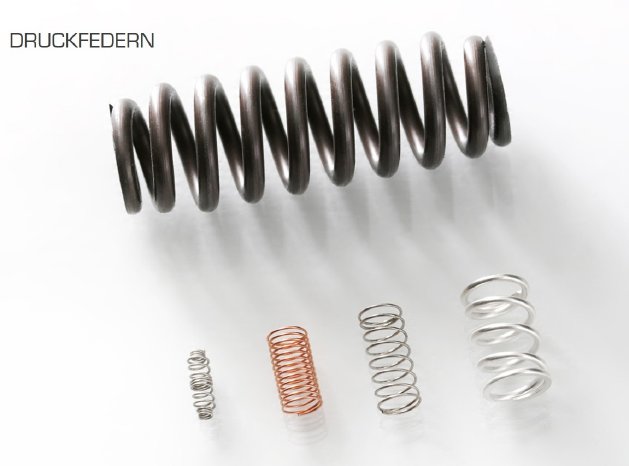

They are used wherever maximum precision is required and just small space available. Because it is the individual components that make your product successful. With our modern manufacturing processes, we achieve an exact grinding pattern even with small wire diameters. This guarantees a clean standing surface and small force tolerances.

Certification according to DIN EN ISO 9001: 2015 and IATF 16949: 2016 is a matter of course for us.