Critical process step: Cleaning

In order to meet the high hygienic demands, and the economic demands in terms of productivity and short downtimes, cleaning processes have to be cleaner and carried out faster. A classic strategy to achieve this is changing the parameters of the cleaning process, e.g. increasing of the temperature or the concentration of the cleaning agents. Well-known materials such as MVQ silicone, NBR, HNBR, FKM, EPDM and conventional PTFE reach their limits quickly. Usually, the temperature cannot be increased further with the existing materials or the materials have to be altered so that they may no longer be compliant with statutory requirements. In addition, most of the materials tend to intrude into the pipe under strong stress in extreme conditions. That leads to flow losses and dead spots, which is a new additional risk for contamination. Thus, these types of gaskets are the limiting factor for a further increase in productivity while maintaining the hygienic standards. In addition, higher temperatures and higher use of cleaning agents are also cost factors that affect profitability negatively.

A new material for new requirements

The solution for the high hygienic and economic requirements on a gasket is in the durable, modified and restructured PTFE material GYLON®. In the production process, numerous layers of PTFE arranged in different directions are calendered and sintered. The result is a material which is resistant to tensile stress and greatly reduced in cold flow. Gaskets made of this modified restructured PTFE have a high compressibility and recovery, are very flexible and do not break under high stress. These gaskets meet the highest requirements in terms of safety, stability, service life, preventing of dead space, and temperature. GYLON BIO-PRO® PLUS gaskets manufactured from this material have all the relevant approvals, like 3-A Sanitary standards and TA-Luft, and contain neither carcinogenic phthalates, bisphenol nor animal ingredients.

A new way in cleaning

The surface tension of the new GYLON BIO-PRO® PLUS gasket is very low, thereby preventing the adhesion of materials to the gasket. This property has also been independently verified by a 3-A 20-27 test conducted at the Element Materials Technology testing laboratory in the USA. Comparative tests demonstrated cleanability identical and in some respects superior to that of polished type 316 stainless steel. At the same time, the intrusion into the interior of the pipe is greatly reduced. This means the new gasket behaves like the pipe itself during the cleaning of the production line, and therefore is no longer the limiting factor for the cleanability. This allows resetting the cleaning parameters, in particular temperature and concentration of the used cleaning agents, and in good conditions to reduce them. This could lead to saving of resources with the same cleaning result, which is a completely new way in reaching the desired hygienic standard. The full effect can be achieved in particular in new facilities, since with the GYLON BIO-PRO® PLUS gaskets an EHEDG design can already be taken into account in the planning phase and thus a EHEDG certification of the entire facility with reduced cleaning parameters is possible.

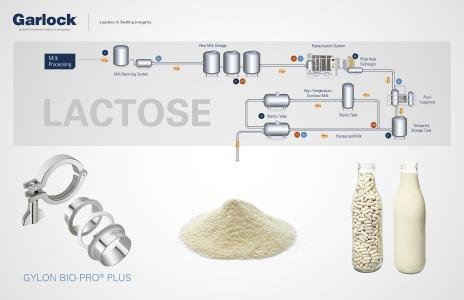

New PTFE gasket for the lactose production

The new, pure PTFE gasket GYLON BIO-PRO® PLUS by Garlock meets the stringent requirements imposed by the pharmaceutical industry as regards sealing properties for the lactose production. This product line, specially tailored to the milk processing industry, meets international standards and regulations, is available in all standard sizes, and is universally applicable.