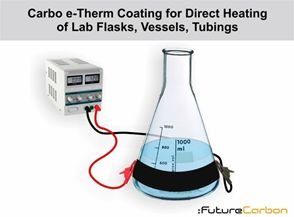

FutureCarbon is again attending nano tech, the world's biggest nanotechnology show. Included in its exhibits is the electrically heated coating Carbo e-Therm UHT, an innovation for heating solutions using temperatures up to 500°C. The big attraction with this high-temperature heating system is that the coating can be applied by the simplest techniques such as squeegeeing or brushing. A non-hazardous low voltage - 12 or 24 V for example - is enough to directly heat lab flasks, machine parts, vessels or samples without creating hot spots.

This heated coating shows the way to entirely new industrial applications calling for very high process temperatures.

FutureCarbon is exhibiting at booth E12 at the nano tech show, and looks forward to seeing you there. If you would like to spend more time talking to us about something of interest, you can arrange a time and date in advance: phone +49-(921)-507388-40 or e-mail sales@future-carbon.de.