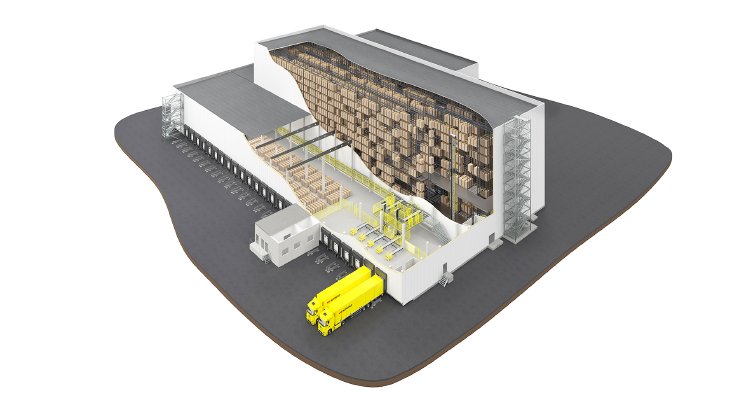

The future high-bay warehouse will primarily accommodate dry goods. EDEKA opted for an automatic high-bay warehouse to create additional storage capacities and achieve the desired performance at peak times as well.

The regional warehouse in Gochsheim receives goods from EDEKA suppliers as well as goods directly from the EDEKA central warehouse. After goods-in, the pallets are transported on a pallet conveying system to the high-bay warehouse (HBW) where the goods are temporarily stored. Each aisle in the HBW is equipped with two picking levels each working according to the tunnel picking concept. The pallets stored temporarily in the high-bay warehouse are supplied to ergonomically optimized picking work stations using gravity roller conveyors. There, the cases are picked manually onto the corresponding roll containers or pallets and transported to goods-out on a special roll container conveying system. If a store requests single-item pallets, these pallets are directly retrieved from the high-bay warehouse and automatically transported to goods-out on a pallet conveying system.

The SSI Schaefer logistics software WAMAS® is in charge of warehouse management. The software has been in use at the majority of the EDEKA companies throughout Germany since 2003. The order is complemented by a service and maintenance contract for the location.

Completion and commissioning of the new logistics complex is planned for 2021.