SSI Schaefer will construct an 8-aisle automated high bay warehouse to accommodate approx. 38,000 Euro pallets for tegut... The rack layout is based on the product range of tegut… with regard to storage capacity and performance, and is divided into single and double-deep racks. tegut... focuses on sustainability and for this reason, the energy-efficient SSI Exyz storage-retrieval machines will be deployed. If required, individual aisles can be switched off.

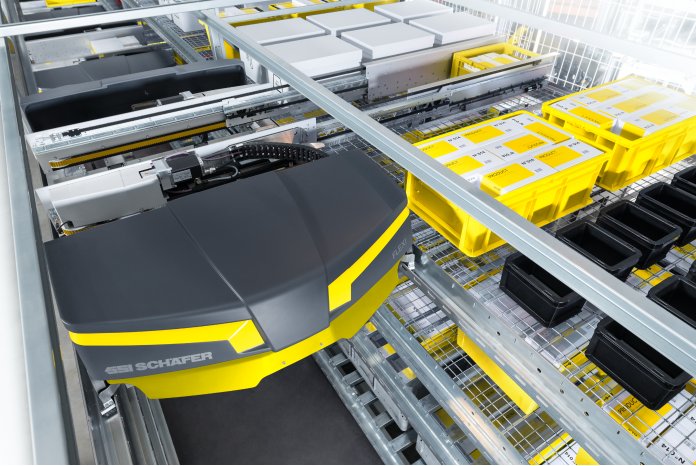

The automated miniload system has a storage capacity of 85,000 bins. The system will have 15 lifts and 130 SSI Flexi shuttles responsible for picking in five aisles and on 26 levels. The SSI Schaefer scope of delivery also includes 73,000 storage bins to store products in the shuttle warehouse. These bins are used to transport the items to and from the picking locations.

A corresponding conveying system for large and small load carriers connects the automatic storage areas to the seven picking work stations with state-of-the-art ergonomic standards. In order to ensure that processes in the logistics center run smoothly and efficiently, WAMAS® logistics software is used. The system layout already considers future growth so that extensions of the high bay warehouse, shuttle warehouse and work stations are possible at a later date.

Building construction will start in summer 2021 and go-live is scheduled for 2023.