- The feed size, defined by its smallest cross-section

- The motor power and speed

- The cutting geometry of the rotor

- The effective area and aperture of the sieve inserts

- The air throughput to discharge the milled particles

The sample throughput per unit of time and the required fineness of the ground sample is determined by these parameters. The cutting and shearing effect of the blades used is generally insufficient to achieve levels of fineness below 0.2 mm, without making use of another mill e.g. variable speed rotor mill, planetary mill will be necessary to obtain further size reduction.

Where the performance demands are very high or the material is particularly problematical we also suggest using the universal cutting mill PULVERISETTE 19 in addition to the standard cutting mill PULVERISETTE 15.

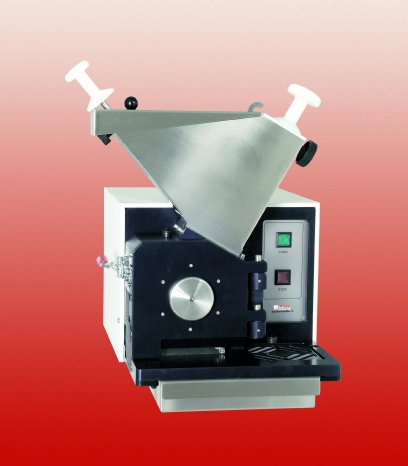

In the standard configuration, the PULVERISETTE 19 is supplied with a V-shaped cutting rotor; its cutting geometry results in fewer blockages even when larger or harder materials are processed than with a parallel cutting rotor. It also “draws in” the material better, forcing the material through the cutting gap better than a disc rotor. Like our competitors we also offer rotors with parallel cutting and disc geometry, however only as special rotors for very specific and limited applications. We are the sole provider of V-shaped cutting rotors.

The feed size plays a crucial role for bulky materials, in particular electronic scrap, heterogeneous waste, plastics, and plant parts. The maximum feed size for the PULVERISETTE 19 is 70 x 80 mm. The rotor speed has a decisive influence on the throughput: at high speed, such as with the PULVERISETTE 19, the air throughput and the cutting speed are higher, resulting in a higher material output. In addition, electro statically charged particles are fed through much better. Slight disadvantages in comparison with cutting mills that run more slowly arises mostly with heavy oil- or fat-containing materials due to the incidence of oil separation.

The effectiveness of the cutting mills is significantly influenced by the air flow, especially for light materials. If, despite fast-rotating rotors, the normal airflow is not sufficient for effectively moving the material out of the grinding chamber, we can connect a cyclone-sample exhauster to the PULVERISETTE 19 significantly improves this performance parameter.

Another competitive advantage of the PULVERISETTE 19 is the easy cleaning thanks to the ease of removing the rotor and sieve without tools; this has not been achieved consistently by any other manufacturer, with the resulting cleaning downtime often being longer than the actual grinding time.

What happens if the capacity of the PULVERISETTE 19 is insufficient or it is obvious that the PULVERISETTE 19 cannot achieve the appropriate level of fineness but a still higher level of throughput or larger feed size is required? For such applications FRITSCH offer a combination of the universal cutting mill PULVERISETTE 19 and the power cutting mill PULVERISETTE 25 plus an integral sample divider. This cutting mill combination was originally developed for initial inspection of waste deliveries to landfill sites but has since proven itself in many fields of application with its high throughput.

Important applications of the PULVERISETTE 19 in addition to comminution of plastic currently include the inspection of secondary fuels in the cement industry (in Germany according to the Technical Instructions on Municipal Waste) or sample preparation for evaluation of RoHS conformity. For the purposes of the RoHS directive (Restriction of the Use of certain Hazardous Substances), the grinding elements of the PULVERISETTE 19 can also be supplied in a chromium-free quality (the expression “heavy-metal-free” often used here is incorrect. Such steels do not exist; however, “chromium-free” is completely satisfactory for this application).

We see the PULVERISETTE 19 as a very flexible and universally acceptable high-performance cutting mill superior to the competition in many respects. We would be happy to prove this at any time. Our laboratory director, Mr. Gerber, would be pleased to demonstrate our advantages with a direct comparison with the competition by processing your customers’ samples free charge.