Lead is a toxic heavy metall. Approx. 90% of the incorporated lead is deposited in the bones and the teeth. Because lead is released very slowly, it will be accumulated over the time in the body. This is dangerous especially for children.

The European Norm EN 71-3 regulates the limit of lead in toys. Furthermore the US norm ASTM F 963-07 regulates the concentration of lead in paints and coatings for toys (max. 600mg/kg).

An adequate sample preparation is necessary to determine if toys fulfil these norms.

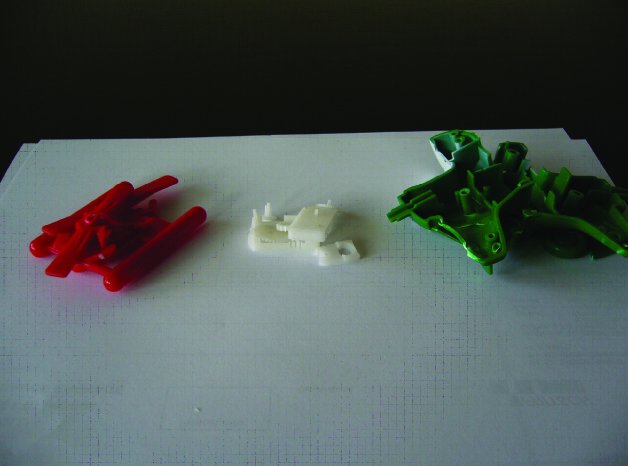

The first step is to separate the different parts of the sample.

For the pre-grinding we use the Universal Cutting Mill PULVERISETTE 19 or the Power Cutting Mill PULVERISETTE 25. The main advantage of these mills is, that you can remove all grinding parts without an additional tool. This makes them very easy to clean and cross-contaminations are avoided.

After an adequate sample dividing, the material is milled with the Variable Speed Rotor Mill PULVERISETTE 14 to the analysis fineness of 200-500µm.

For the Cutting mill we recommend knives made of chromium-free iron or tungsten carbide. To avoid thermal degradation in the Variable Speed Rotor Mill the sample can be embrittled with liquid nitrogen or with dry ice.

The analysis now can be done with XRF spectrometer.

The sample preparation showed here was done with a plastic toy. Of course any wooden toy is also applicable.

Cutting Mills are also the most effective laboratory mills for pre-crushing and fine grinding of other soft to medium-hard, fibrous or tough materials (including plastics), as well as for the preparation of heterogeneous substance mixtures and for sample preparation according to EU directives RoHS/WEEE.

FRITSCH offers due to its different models of cutting mills and extensive range of further grinding mills for each special use and application a suitable instrument.

Please use our instrument search engine as well as our grinding report data base on the FRITSCH-Homepage under www.fritsch.de – sample preparation – Solutions. Here you will find your suitable instrument as well as a comparative grinding report comparable with your application.