FOBA Laser Marking + Engraving, an internationally leading manufacturer of marking laser systems and workstations with integrated vision, launches its MarkUS marking software update 2.11. with advanced marking features. Additionally, the new “Advanced Operator PlugIn” (AOP), a graphical user interface for clear process visualization and on-screen operator instructions, enables quick, intuitive, secure and almost error-free operation while requiring minimum user interactions through all marking steps.

The process visualization includes a part preview and a direct visual verification feedback. The screen is clearly arranged with interactive operator instructions, information about the processing status and colored indication fields for each part passing through the visual inspection: green for good and red in case of bad parts.

Safe data transfer protects production from incorrect entries: A bar code scanner, with direct ERP integration, transfers all job related data into the laser marking system. By automatically merging variable data like UDI or other codes with corresponding job data in the ERP system, the new AOP allows users to significantly reduce setup time. Database connectivity, for faster job preparation and less transfer errors, contributes to production efficiency.

Depending on the kind of production and customer needs, user instructions will be specifically adapted, status information and process visualization language can be selected in English or German. For documentation purposes, the system generates history files to report all operators actions. Batch processing is possible and parts or products can be marked single-sided or multi-sided, up to six sides per part with each side being marked with individual settings.

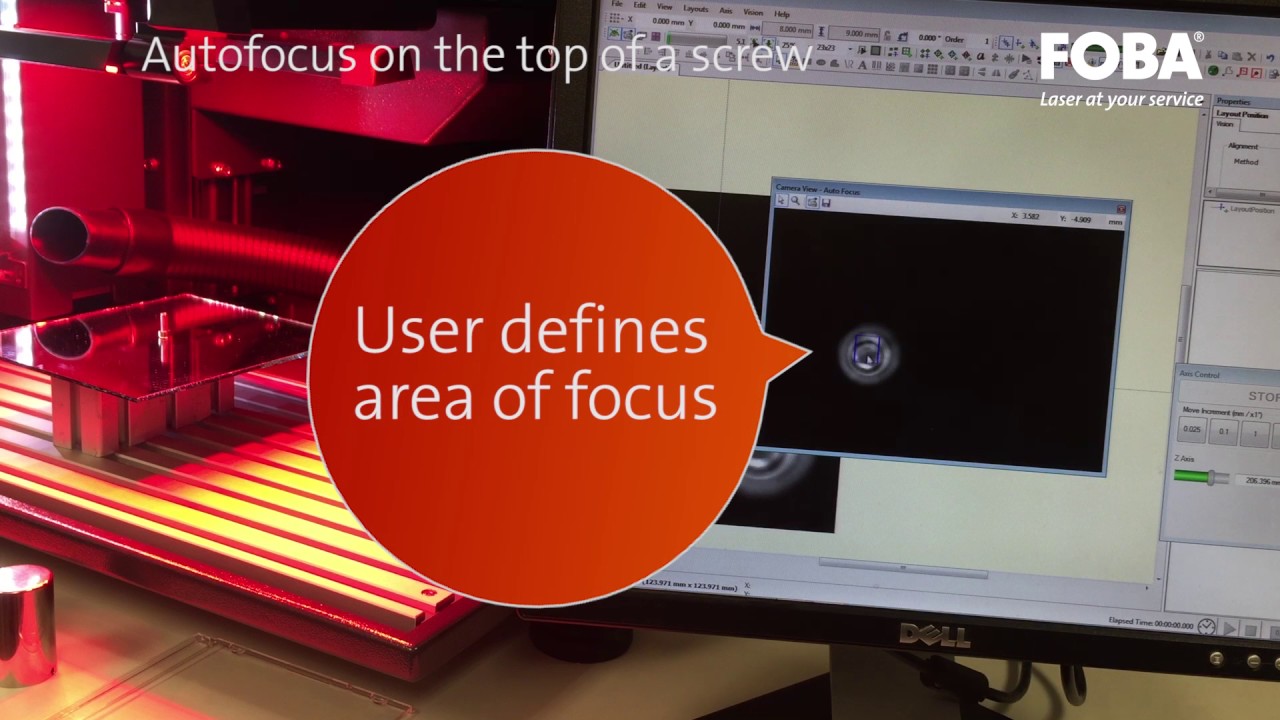

With the new autofocus feature, the user can bring the laser in focus much easier and faster in a single click operation. Finding the best focus becomes easier on almost any finished or colored material. The autofocus function is fully integrated into FOBA’s vision system, is stable and maintenance-free.

High quality laser marking is essential to ensure sustainable traceability of parts and products. The new PlugIn is a perfect supplement for FOBA’s “HELP” (Holistic Enhanced Laser Process), which is a closed-loop vision-based marking process. HELP is capable of verifying the product as well as the marked content and the proper positioning before, during and after laser inscription. Scrap can be reduced by up to 80 percent. Automotive industry, medical device manufacturers, mechanical engineering companies and others benefit from HELP’s outstanding efficiency for various direct part marking applications.