Whether cosmetics packaging, housings or automobile parts are involved – products made of plastic can be found in practically all industries and all spheres of life. With the help of coatings, these products are frequently provided with appealing optics and haptics, an individualised appearance, resistance to mechanical, chemical and physical stressing, as well as special functional characteristics. And thus companies with in-house painting operations and coating job-shops are facing new challenges due to current trends and changes in numerous industry sectors. These include the use of new and modified materials and material combinations, the realignment of entire industry sectors, shortened product lifecycles and smaller lot quantities, personalisation of products, the digital transformation and more rigorous goals with regard to energy-efficiency and climate protection. The situation is further complicated by cost aspects. All of this results in the need for high quality painting processes which are more efficient, flexible and resource-conserving. Numerous appropriate options will be presented by the exhibitors at PaintExpo from the 21st through the 24th of April, 2020.

From Pre-Treatment to Quality Control

Pre-treatment is taken into consideration first of all: alternatives to conventional power washing such as plasma and CO2 snow-jet technology often make it possible to reduce cleaning process costs and footprint, and to integrate fully automated cleaning processes into the painting line. Due to the fact that neither chemicals, water nor drying are required for either of these processes, they also make good sense where environmental and energy-saving aspects are concerned. Beyond this, no heat is transferred to the component which could cause substances used in the plastic such as release agents, additives or filler materials to subsequently migrate to the surface from deeper layers, thus resulting in adhesion problems. Electrostatic charging of the plastic surfaces can be counteracted by means of ionisation.

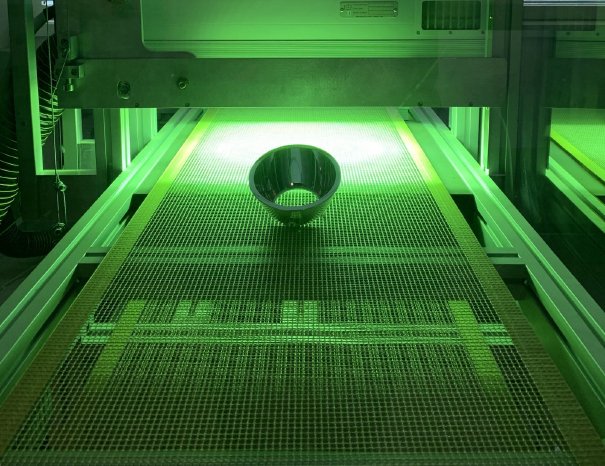

Where the paints themselves are concerned, new developments resulting from so-called single-coat systems are making it possible to reduce the number of required painting steps, at the same time achieving strong resistance to external influences on painted surfaces. One of the issues being dealt with in many industry sectors with regard to increased sustainability involves alternatives to galvanising with chrome(VI). The paint manufacturers have developed various solutions to this problem. Depending on the application and the requirement, these include three-coat paint systems or economically efficient single-coat solutions. With their diverse colour variants and effects, these paints are more than just an alternative to a galvanically applied chromium coating. Plasma-vacuum coating in combination with UV paint is a further option. And significantly more painting solutions are available in the meantime, which are laid out for polymerisation with LED-UV technology. UV paints which make it possible to exploit the advantages offered by LED-UV curing – amongst others the curing of heat-sensitive substrates, energy-efficiency and immediate readiness for use after being switched on – are not only available for the metallization of plastic surfaces, but rather for conventional painting tasks as well. Innovations for powder coatings on components made of plastic will also be unveiled.

The trend towards automation is advancing relentlessly – at small and mid-sized companies as well. Reasons for this include increased process reliability and reproducibility, as well as the minimal scrap rates which result therefrom in combination with the respective savings. Painting equipment and robot manufacturers are responding to this need with multi-axis robots specially designed for the coating industry, as well as so-called robot painting cells. The paint application technology required to this end is specifically adapted to the respective customer project. New spray gun controllers permit highly accurate application. All painting parameters can be easily accessed and adjusted extremely precisely. This leads to outstanding reproducibility, uniform painting results and reduced material consumption. In addition to the classic teach-in process, robot motion sequences can also be programmed offline at a PC with the corresponding software. Other automation issues for which new developments will be presented include paint preparation, paint conveyance, dosing and colour changeovers.

New solutions for automated monitoring of process parameters such as paint quantities, temperature, process air and the spray jet, as well as logging and evaluating the resultant data, are also available. Furthermore, innovative developments permit process-integrated quality control of the coated surfaces – for example non-destructive, contactless coating thickness measurement on still wet as well as already cured paint layers.

Selecting the right process is a prerequisite for a resource-efficient, sustainable, high-quality coating process: whether liquid painting, powder coating, a UV painting process or a combination is best depends on, amongst other factors, the product to be painted, the required quality and the necessary degree of flexibility. And it pays off to closely scrutinise processes which have been in use for years or even decades, and to compare them with alternatives. Thanks to the fact that all technologies throughout the entire process sequence are exhibited at PaintExpo, and because all relevant suppliers are represented at the event, this comparison can be conducted very efficiently at the world’s leading trade fair in a targeted fashion.

Further information and a preliminary exhibitor list can be accessed at www.paintexpo.com.