If e.g. in the construction engineering an angle is inaccurate due to deterioration of the foundry mold or variation of the extrusion pressure, the EyeSens Angle will recognize this.

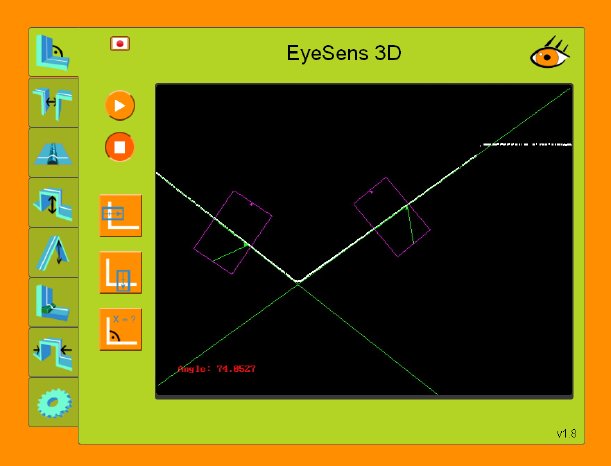

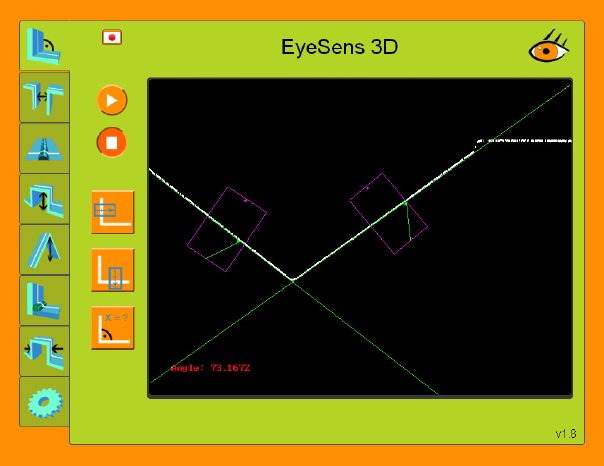

EyeSens Angle consists of a hardware and a software component. The hardware is a line scan sensor, which projects a laser line onto the test object. The profile of the laser line is then captured and processed by the sideways mounted camera.

For parameterizing the inspection program, the EyeSens Angle has as software component an integrated web interface available. The user only has to type the IP address of the camera into the web browser and the web interface will be displayed. The browser now shows the user interface, which includes the command for measuring an angle. Due to intuitively comprehendible icons, the test object can be easily configured.

Thanks to the surface profile of the laser, angles and edge positions can be easily measured, calculated and controlled.

After the parameterization of the individual measurement tasks, the respective results can be calculated. This way several angles can be measured in fast succession. Therefore measurement tasks can be carried out without drawn-out calculation by hand and the measured values can be output by the sensor in real time.

The laser line scan sensor has a frame rate of up to 1 kHz. The measurement range starts with a working distance of 80 mm to the sensor. The compact housing allows the sensor to be used quite flexibly as a fixed measurement unit or for a moving operation.