The camera possesses a measuring rate of 120 Hz and allows precise temperature measurements of target objects as small as 1.5 mm. The temperature range of the camera reaches from -20°C to 900°C and optionally also up to 1500°C. Additionally the infrared camera has a spectral range from 7.5 to 13 µm.

The application areas of EyeVision combined with the infrared camera are manifold and include the automotive and food industry as well as the plastic and solar industry.

For example the infrared camera can be used at the production of light weight construction trim parts in the automotive industry. As e.g. the plastic sheets need to be heated before being modeled into perfect trim parts, temperature measurements are carried out by the EyeVision software and the Optris IR-camera. Therefore single values as well as temperature profiles of the surface can be evaluated.

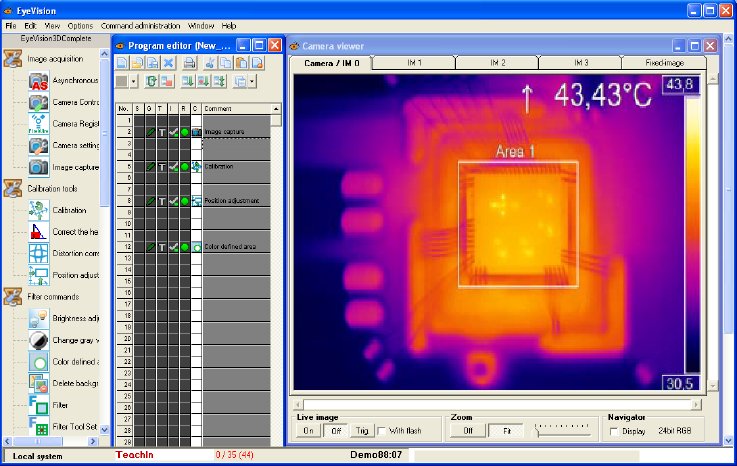

Even in combination with an infrared camera, the user interface of the EyeVision software stays the same.