All this is no longer efficiently achievable with single-point numerical simulations. Instead, automakers need to tightly couple the engineering and the manufacturing world in order to make the right choice as early as possible.

Join our upcoming webinar series to achieve confidence in the optimum design earlier and reduce vehicle lead times drastically by predicting physics and processes accurately. Each Webinar of the series will cover the problematics related to specific assemblies of the vehicle: Doors & Closures, then Body in White, and finally Chassis.

INTRODUCTORY WEBINAR

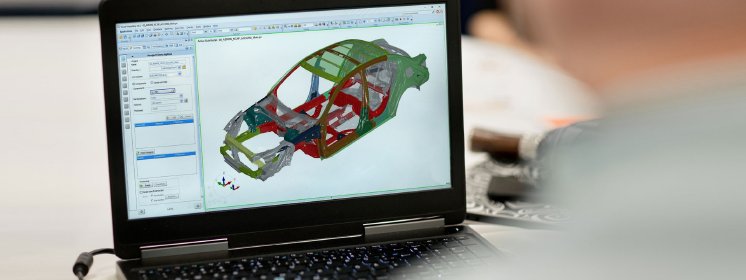

Multi-Material Body and Chassis Assemblies with Confidence

Date: May 6th - 10am CET/12pm ET

WEBINAR 2

Assembly Distortion Control and Perceived Quality | Doors & Closures

Date: May 27th - 10am CET/12pm ET

WEBINAR 3

Assembly Distortion Control and Crash Prediction | BiW Assemblies

Date: June 17th - 10am CET/12pm ET

WEBINAR 4

Assembly Distortion Control and Fatigue Prediction | Chassis & Suspension

Date: July 8th - 10am CET/12pm ET