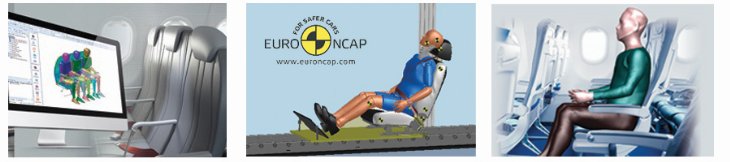

As the air travel market has become increasingly competitive, airlines are looking for opportunities to differentiate themselves, and offer a more enjoyable experience to their passengers. To this end, engineers are striving to improve cabin equipment, and more specifically, what passenger comfort most depends on: the seats. ESI Virtual Seat Solution 2016 enables seat manufacturers to virtually assess the performance and comfort of their seats with respect to many criteria including living space, static and thermal comfort of the passenger, and the capacity of the seat to absorb the in-flight vibrations.

Aside from the need to meet passengers’ growing expectations in terms of comfort, future aircraft seats will have to answer challenges linked to weight reduction as a means to enable airlines to save substantial amounts of fuel. This must be achieved without impacting passenger safety and in compliance with evolving safety regulations.

Today, aeronautic manufacturers are placing their trust in virtual testing to accelerate product development. French company Expliseat, for instance, swiftly gained certification for their revolutionary Titanium aircraft seat, the lightest seat ever certified by the European Aviation Safety Agency (EASA):

Virtual Prototyping is a proven industrial approach to pre-certify the manufacturing process and performance of an innovative product, such as our Titanium seat,

commented Vincent Tejedor, CTO of Expliseat

Our experience working with ESI’s Virtual Seat Solution confirms the efficiency of this solution in speeding up innovation. Virtual Seat Solution has helped us reduce drastically the development time usually required to design an innovative product, and has allowed us to increase the business value of our company in record time!

Already a proven software solution in the automotive sector, Virtual Seat Solution 2016 now provides a complete end-to-end Virtual Prototyping solution dedicated to the aeronautic sector from seat modeling to virtual performance testing, thanks to virtual human models, all the way to virtual certification.

Enhancements answering challenges in the automotive sector:

The new Virtual Seat Solution 2016 also delivers key improvements for the automotive market to enable performance assessment early in the seat development process. With its new functionality for guided seat model generation, Virtual Seat Solution 2016 allows engineers to easily define new seat concepts. They can now efficiently also work through the initial development steps re-using previously modeled components and changing them easily as their project progresses. Virtual Seat Solution automatically updates the seat model to compute the performance of the seat with the new components, providing significant flexibility and time gains.

In the frame of whiplash testing to ensure passenger safety, the ChinaNCAP process is now supported by Virtual Seat Solution 2016, completing the software’s existing capabilities for assisting EuroNCAP and JNCAP certifications. The dummy model BioRID II v.3.0 is now available in addition to the already provided BioRID II v2.6. Also, a new seat positioning tool is available to easily adjust the seat in the configurations defined in NCAP protocols. Lastly, the computation of the numerous pulse severity levels during the whiplash sled tests, can now be prepared simultaneously for a unique launch.

Read here a customer testimonial from Japanese seat manufacturer Tachi-S about performing whiplash testing with Virtual Seat Solution.

For more information on Virtual Seat Solution, please visit: www.esi-group.com/virtual-seat

For more ESI news, visit: www.esi-group.com/press

Connect with ESI on LinkedIn, Twitter, Facebook, and YouTube.