SYSTUS benefits from 40 years of R&D in Finite Elements Analysis (FEA). The software was originally developed by Framatome (now AREVA NP) to support the design of their nuclear power plants and to perform regulatory analyses — all virtually. Today, SYSTUS has become an industry-proven solution for an extensive range of regulatory analyses mandated by international standards for nuclear engineering. It specifically addresses the requirements of the ASME code[1], standard issued by the American Society of Mechanical Engineers, and the French standard, published by AFCEN and known as RCC-M (Règles de Conception et de Construction des Matériels Mécaniques des Ilots Nucléaires2 REP3).

SYSTUS 2017 brings new enhancements for conducting regulatory analyses, including new analytic options, and a better legibility of results. It introduces a Differential Method (RCCM-MD) for second category analyses that can help industrial manufacturers and their suppliers overcome major issues related to load changes over time and variations in the directions of principal stresses, as these interfere with the computation of the amplitude of the equivalent stresses Sn and the usage factor U.

In the field of fracture mechanics, SYSTUS allows industrial manufacturers and their suppliers to perform brittle and ductile fracture analysis. Working with AREVA for over 6 years, the ESI SYSTUS team has developed an innovative eXtended Finite Elements method (X-FEM) that enables the analysis of defects without the need to model the cracks explicitly — hence reducing complexity and saving time. With ESI’s X-FEM method, the representation of defects is carried out using the Level-Set Method and specific enrichment functions.

SYSTUS 2017 includes enhancements for fracture mechanics with the X-FEM method, including new and simplified commands to improve software ergonomics. The version delivers strong efficiency improvements and offers results very close to those obtained with Finite Element Method (FEM) analysis with meshed cracks. Furthermore, with SYSTUS 2017, the X-FEM method now takes into account plasticity, includes meshing with quadratic elements, and enables the computation of the Energy rate using the Theta method.

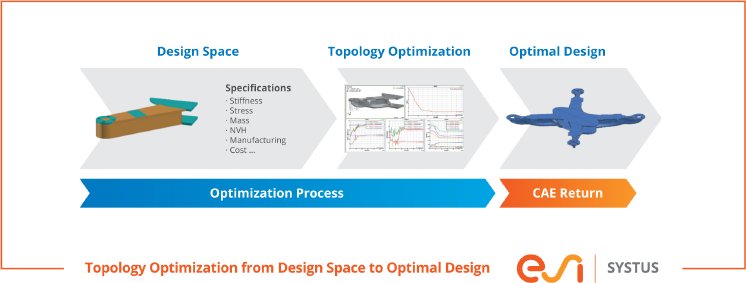

Finally, SYSTUS 2017 addresses specific needs in the automotive and aeronautic industries for the first time by offering shape optimization. Here, SYSTUS provides mathematical solutions based on the level-set technology and enables manufacturers to access precisely the optimal shape.

1 ASME code : Section III, division 1, article NB 3200

2 RCC-M = Règles de Conception et de Construction des Matériels Mécaniques des Ilots Nucléaires. In English: Design and construction rules for mechanical components of PWR nuclear islands

3 REP = Réacteur à Eau Pressurisée. In English: Pressurized Water Reactor.

See RCC-M : Paragraph B3200

For more information about ESI SYSTUS, please visit: www.esi-group.com/systus

Join ESI’s customer portal myESI to get continuously updated product information, tips & tricks, view the online training schedule and access selected software downloads: myesi.esi-group.com