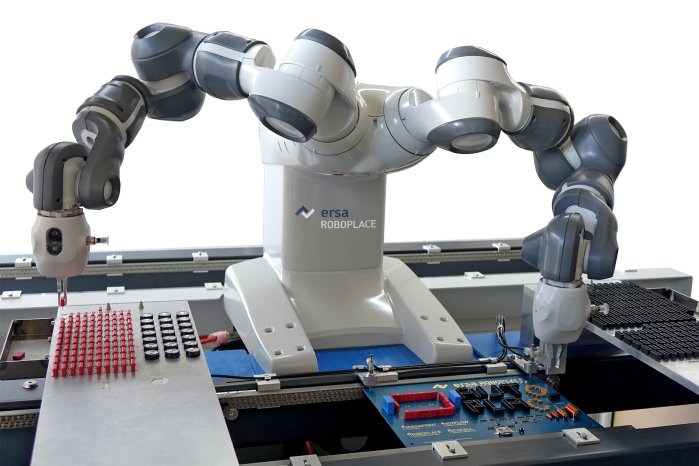

A large number of visitors from all over the world visited the 400 m² Ersa booth and where overwhelmed by the number of machines, systems and applications exhibited, many of them for the first time in the world. More than that: In, for a trade show untypical fashion, a gratifyingly large number of orders were placed directly at the show – a sure sign that the innovations displayed by Ersa were able to convince its viewers. It also is a strong indication that the business year 2015 is heading for another year of record results! For both, the hand soldering units, the “tools”, as well as for the “machines”, numerous highlights exerted a strong draw on the visitors – one of many eye-catching systems was the collaborative Ersa ROBOPLACE. The reaction of the expert visitors indicated that the idea from Ersa, viz. to automatically populate individual through-hole components, hit the nerve of the times. The ROBOPLACE marks another important and correct step in the direction of “fully automatic selective soldering”.

Equally enthusiastically received was the flagship VERSAFLOW 4: The newest generation of the high-end selective soldering systems is of particular interest for the automotive industry – and more precisely for the manufacture of batteries for hybrid vehicles. The automated soldering of these large and very heavy, weighing up to 18 kg, board assemblies, already partially mounted in aluminum housings, was up to now a huge challenge for any electronic manufacturer. With its large 508 x 508 mm working area, the VERSAFLOW 4 is destined to close this gap. And, on this top-of-the-range model, the axes of the solder bath are automatically controlled by programs.

Enthusiasm also in the stencil printing technology: Ersa surprised the industry with the brand-new VERSAPRINT 3D stencil printer with integrated 3D inspection camera. The printer combines stencil printing and 3D inspection in one system. This allows for a level of automation in stencil printing not seen before and ensures a constant and as much as possible operator-independent process quality. Quite obviously, Ersa’s developers have acted here in line with the needs of the general market: Proof for this are the firm orders placed at the show for the new model, which immensely pleased Ersa’s staff.

Nevertheless, this was not yet the end of the innovations displayed by Ersa. The HOTFLOW 3/20 VOIDLESS reflow system was shown – and, similar to what happened with the ROBOPLACE and the VERSAPRINT 3D, it seems that the electronic manufacturing industry had just been waiting for the technology shown: Inline reflow soldering that is virtually free of voids, and still with high throughput and low operating costs. Feedback for this new technology was so overwhelming, that the Ersa team will have to work down a long list of customer inquiries.

The news from the rework world was also welcomed by the visitors: From the first time shown “rework out of a box” entry level model HR 200, or the new hybrid rework platform HR 550 with program-supported component placement right up to the high-end units HR 600/2 and the VOIDLESS module, they all generated a large interest which translated directly into purchase orders. The expert visitors were equally impressed by the high-performance soldering iron i-TOOL HIGH-POWER with its tremendous 250 Watt power.

The feedback received during the four show days in Munich has shown that Ersa is on the right track with those products and technologies it displayed – the many projects and the many orders received confirm this. They are the reward for the hard work of the Ersa team. For the sales department, though, the outstanding success means a lot of work over the next 12 – 18 months. And then it is almost productronica again – so, to productronica 2017!