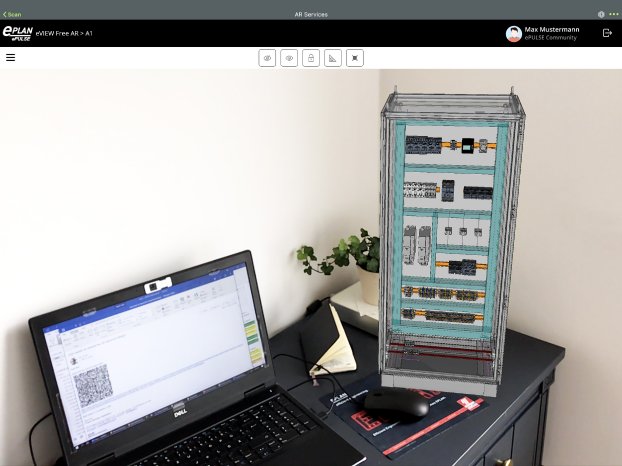

With Eplan eView Free AR, a new augmented reality (AR) application, Eplan now brings the digital twin wherever users happen to find themselves. Designers can share their 3D designs of the control cabinet layout from Eplan Pro Panel with co-workers and business partners via the cloud. Eplan Program Manager Digitalisation Tim Oerter oversees the development of AR solutions and explains how to get started with Eplan eView Free AR: “A control cabinet is constructed in Eplan Pro Panel and subsequently uploaded to the Eplan ePulse cloud environment. This makes it possible to share 3D designs with other users within an ePulse organisation.” This also automatically generates both a link and a QR code that can be forwarded to the desired recipients. They can then use their smartphone or tablet computer to scan the code using the gratis app Vuforia View from PTC. Now the 3D design can be displayed anywhere using the camera of the end device – and can thus be projected onto a desktop or in the production environment as examples. Changes can also be made by touching any control cabinet components: simply tap the component and the system opens the 2D view of the schematics, for instance for further finetuning using the redlining and greenlining functions.

Development continues

Solutions provider Eplan sees further opportunities in the use of AR technology – particularly in the areas of service and maintenance. Developers are currently working on a fee-based app that will be offering many more features in the future. The goal is create a direct link from the actual model of a control cabinet to its digital twin. By scanning a QR code attached to the control cabinet, service personnel will then be able to access all the machine’s data. Another goal is to introduce redlining and greenlining functions in the production environment and thereby create a direct possibility for troubleshooting.

Background information on augmented reality

Augmented reality makes it possible to superimpose a digital model into the real environment and enhance it in this way. In contrast to virtual reality, a user isn’t immersed into a virtual world using VR goggles. Instead, virtual objects are projected into a person’s actual environment. All one needs is a smartphone or tablet computer with a camera.

Find out more, including an informational video, at:

www.eplan-software.com/eplan-eview/