BST COATINGControl achieves the best possible production results by controlling itself with high-precision measurement technology and optimizing the web running processes with intelligent control technology. The reliable real-time measurement of the coating layers reduces the number of line stops. In combination with the FRAMEGuide web guiding system, BST COATINGControl achieves maximum control accuracy through robust edge detection via a central control unit and closed-loop image processing algorithms. Thanks to continuously perfect coating positioning, no further manual offset correction by the machine operator is required. This interaction is particularly relevant for applications in the Battery, Fuel Cell and Printed Electronics industries. "In this segment, the smallest deviations in the coating lead to unacceptable quality losses and thus to rejects," explains Kortekamp. For example, if an electrode's coating is not perfectly congruent on both sides, the subsequent battery cell falls short of the capacity required by the industry and cannot be sold. BST COATINGControl prevents this misalignment with unprecedented precision: "The achieved accuracy of the entire system is twice as high as required by the industry. Thanks to the robust and easy-to-perform calibration routine, even the requirements for measuring equipment in the automotive industry are achieved," Kortekamp is pleased to report.

BST COATINGControl has been developed according to customer requirements.

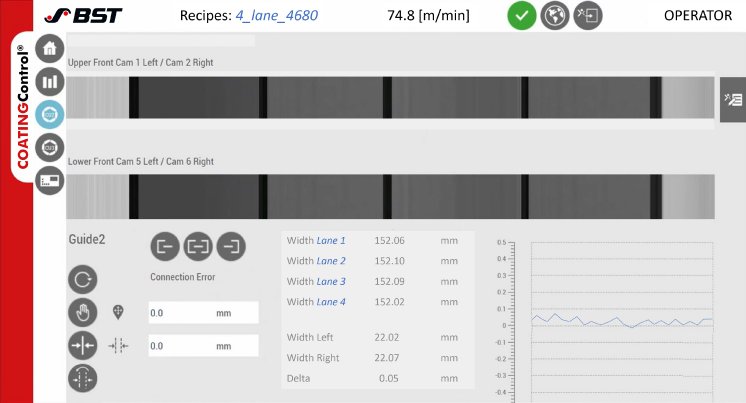

The Bielefeld-based company maintains close and long-standing customer relationships. As a result, the manufacturer is well informed about its customers' very specific challenges and solution requests. In addition, the company has extensive experience with measurement and control systems in a wide range of industries. Both know-how and customer knowledge have been combined in the 2nd generation of COATINGControl, which provides live camera images of the coating as well as an intuitive user interface. The system detects minimal production defects, takes immediate countermeasures and thus reduces the reject rate. As a result, the entire system runs more efficiently, output quality improves, and the material usage is more economical. COATINGControl ensures that the coating edges on the top and bottom of an electrode are completely congruent, so that more end products meet the customer's specifications and overall productivity increases.

Error rate declines, potential for productivity increases

BST COATINGControl relieves machine operators of the burden of monitoring the coating process by removing a complex task from their plate. This is due to the fact that workers must usually keep an eye on the position and thickness of the coating, as well as the drying process, in addition to the coating's quality. With its closed loop control, BST COATINGControl automatically ensures the correct positioning of the coatings. This frees up time for other tasks while maintaining or improving overall quality. The automated reproducible calibration routine also enables short maintenance downtimes. The developer sees the ease of use as a highlight of the system. "BST COATINGControl informs the machine operators comprehensively, intuitively, mobile, precisely about all relevant parameters at all times. They can see the position of the coating at a glance and also receive a live image of both coating sides. Optionally, the user interface can be accessed on mobile devices. This is an advantage when operators are often on the move around the machine during production. With this location-independent overview, it is also easy for semiskilled workers to operate the machines well at all times," explains Kortekamp.