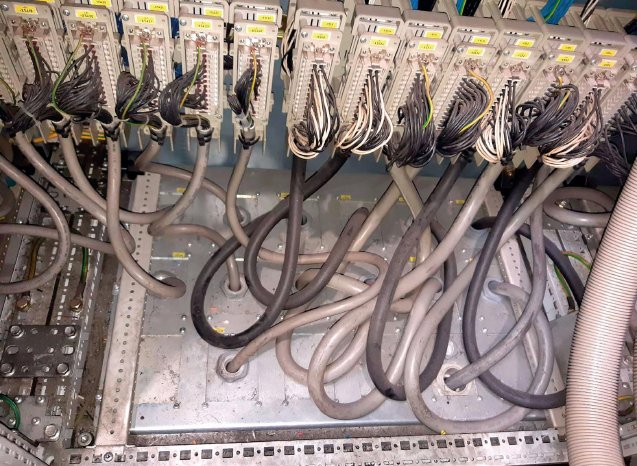

This is not exactly the case with conventional dry ice blasting. The dry ice pellets are hard as ice and can "shoot up" surfaces with impacts at speeds over 1,000 km/h. Plug connections can be torn apart, possibly interrupting operations.

Egger PowAir Cleaning GmbH has been using the KDL Method to clean control cabinets and other control technology for many years. The technology is used in high-speed trains, for example, as well as for the cleaning of control cabinets under full load in many fields of industry and trade. Robert Egger developed this method and registered for a patent in 2019. The brand name "Cold Powair – Cleaning with cold compressed air and nothing more..." is a trademark as well. Businesses in industry and trade are regularly left positively surprised after switching to the KDL Method of cleaning for the first time. "It's incredibly fast and cleaner than ever before. The exhaust immediately removes soiling from the air. We've enclosed one machine, and all the machines around it just kept running. We didn't experience any interference from dust or similar contamination...", explains an experienced sales manager who previously asked his workforce to clean the machines by hand. "It saves us a lot of time and money. Cleaning with the KDL Method from Egger PowAir Cleaning has turned into our STATE of the ART.”