Along with digital supply chain twin, the usual suspects artificial intelligence, Robotic Process Automation (RPA), IoT, immersive experience and Blockchain have gained a seat in Gartner's Top 8. Though one might argue - and Christian Titze states the inevitability for a good reason - the digital supply chain twin will not only be another technology within the Top 8 cluster. In fact, it is the basic foundation to the entire digitization of supply chains.

Data needs context

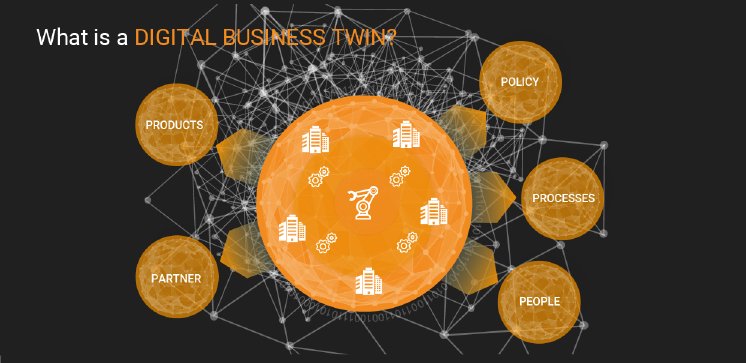

As Gartner states in its press release "a digital supply chain twin is a digital representation of the relationships between all physical entities of end-to-end supply chain processes — products, customers, markets, distribution centres/warehouses, plants, finance, attributes and weather. They are linked to their real-world counterparts and are used to understand the state of the thing or system in order to optimise operations and respond efficiently to changes." Hence, not only is the digital supply chain twin the bridge between the real, profit driven world and the information based, decision driven world. It is also the connector between all the different data sources that link the main 5 Ps of an enterprise to a truly digitalized ecosystem. In an enterprise the 5 P form the main columns of business success: products, processes, people, partners and policy. Though the question remains, how to achieve this in enterprises that are characterized by thousands of disparate systems and an IT that operates at the verge of capacity.

"Due to mass-customization, lot size 1 and ever increasing customer service expectations Chief Supply Chain Officers need to push for seamless end-to-end collaboration throughout their entire eco-system. And they need data from a myriad of different sources to achieve this", explains Hans-Christian Brockmann, CEO of the digital twin company eccenca. "But data without context and a shared understanding becomes noise. To drive digital maturity enterprises need a data management foundation that connects the dots between all the disparate data sources. eccenca clients use semantic capabilities to integrate data and background knowledge to build business digital twins of their products, processes, partners and people. This allows them to drive efficiency, transparency and quality which in turn helps them address issues with key KPIs such as working capital, operating margin, demand-supply-match and customer satisfaction."

Nokia and RFS show the way

Digital leaders like Nokia and RFS (Radio Frequency Systems) already build their next generation supply chain on a knowledge graph driven digital twin infrastructure. Nokia is currently implementing a fully automated and digitalized software delivery process for their B2B portfolio, cutting lead times from weeks to mere minutes. One of the world's leading provider of innovative wireless and broadcast infrastructure solutions, RFS, has minimized data preparation efforts by 50 percent. This and the full integration of disparate production data allowed them to significantly increase production capacity and inventory turnover which lead to an ROI of 200 % within the first 6 months. "Those results show that digitization starts with data and its management", Hans-Christian Brockmann points out. "There are many good but specific solution providers for any use case imaginable. We have seen this often enough in the past. But if the enterprise is not able to connect the 5 Ps, any digitization effort will reach a deadend in silo-ed solutions and - ultimately - data noise instead of insights. There is no alternative to a digital twin that provides full data flexibility and system scalability across any number of use cases"

For more information on the RFS case study: https://www.eccenca.com/...

Also meet eccenca at the APICS Annual Supply Chain Management Conference, Sep 16-18, 2019 in Las Vegas, USA.