The complexity of the requirements in modern plant construction is constantly increasing – from sustainable production to the health and environmental protection to efficient, economic performance. 3M Dyneon TFM Modified PTFE offers a well-balanced solution for many different applications. In recent years this fluoroplastic has proven itself in particular as a lining and sealing material in plant engineering and construction apparatus.

Fully fluorinated fluoropolymers come out on top

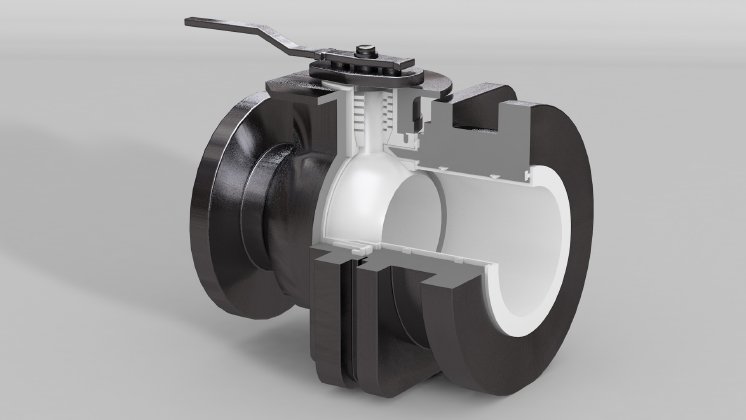

The protection of pipes, tanks and vessels against corrosion is an important factor in the chemical and pharmaceutical industry – for the plant safety and also with regard to the reduction of the continuous operating costs. That’s why more and more industrial enterprises use fully fluorinated fluoropolymers such as PTFE. Above all, TFM Modified PTFE impresses with a very good performance due to its high resistance to temperature and chemical attacks.

Improved weldability and low elongation

The molecular weight of TFM Modified PTFE is around five times lower than that of classic PTFE. This reduces the viscosity of the polymer melt. As a result the TFM particles attach more easily to form a dense, low-void containing polymer structure. Among other things this improves the weldability of the products. At the same time, TFM Modified PTFE is characterised in particular at high temperatures by a comparatively low flow behaviour. This is of great importance, for example, for components that are mounted under pretension.

Longer life time leads to higher profitability

A further advantage: TFM Modified PTFE has fewer effects on the environment, since the material exhibits better sealing properties in comparison with PTFE where volatile chemicals are concerned. At the same time, a longer life time and a lower cleaning requirement lead to shorter plant downtimes and thus to higher profitability of plants.

Areas of use in many industries

The properties of 3M Dyneon TFM Modified PTFE open up a wide range of new applications in many different branches of industry. These include insulation for the electrical and electronics industry, tailor-made solutions for the chemical industry and optimised solutions for the semiconductor industry, for mechanical engineering and for the automotive industry.

3M, Dyneon and TFM are brands of the 3M Company.