The molecular weight of polytetrafluoride ethylene (PTFE) micropowder is around 100 times lower than the well-known PTFE types. This means, however, that this powder is not dedicated for normal compression moulding or sintering, as the finished mouldings would not have any mechanical strength. However, the low molecular weight does permit an even distribution of the powder in the matrix material, giving it the required properties in each case. Problems, such as fibrillation in the manufacture of plastics or difficulties in breaking down agglomerated particles, are therefore obsolete.

Suitable properties in various applications

Numerous applications of PTFE micropowder have improved wear, friction, dry running, non-stick and stick-slip properties in thermoplastics, elastomers and thermosets. They have a positive effect on the lubricating and dry-running operation in oils and greases, particularly when exposed to extremely high pressures and temperatures.

In printing inks for high quality printed materials, PTFE micropowders improve surface quality, such as gloss and scrub resistance and blockages. They optimise the non-stick effect, friction coefficient, corrosion protection, wear resistance, deep drawing properties and spray properties in non-stick and lubricant coatings. Micropowders are also used as a dry lubricant in metal forming processes (wire drawing and deep drawing) because of their good friction properties.

Resistance to chemicals, temperature and weathering

Alongside their non-stick and friction characteristics, PTFE micropowders that are available in four variants are virtually universally chemically resistant. They can be permanently deployed in temperatures ranging from -190 °C to +260 °C. They show no embrittlement or ageing and will not burn under normal conditions. Additionally, they are highly resistant to weathering, particularly to UV radiation and offer very good insulating properties.

Recyclable in a special reactor from Dyneon

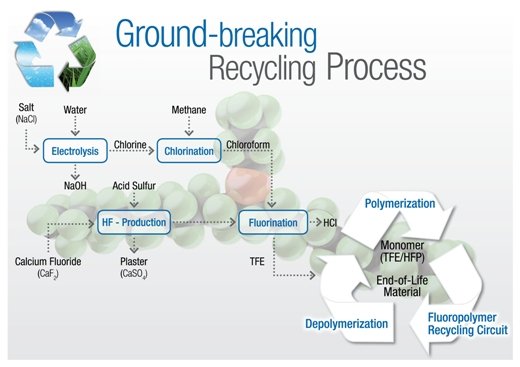

If PTFE waste has previously been thermally recycled or expensively disposed of in special landfill sites, it can undergo high quality recycling in the future. Dyneon GmbH is currently building a pilot plant with support from the German Federal Ministry for the Environment and in collaboration with the University of Bayreuth. Waste is heated up in a special reactor, split into its primary materials, cleaned and then merged together again to form valuable PTFE without any loss of quality.

The potential for protecting nature and the environment is enormous. Experts estimate that up to 5,000 tonnes of PTFE waste currently arises when PTFE is processed in Europe. If the project goes ahead successfully, around 2,500 tonnes of chlorine can be saved and 5,000 tonnes of CO2 emissions and 5,000 tonnes of acid waste can be prevented. The project also helps to save valuable resources, for example, fluorspar.