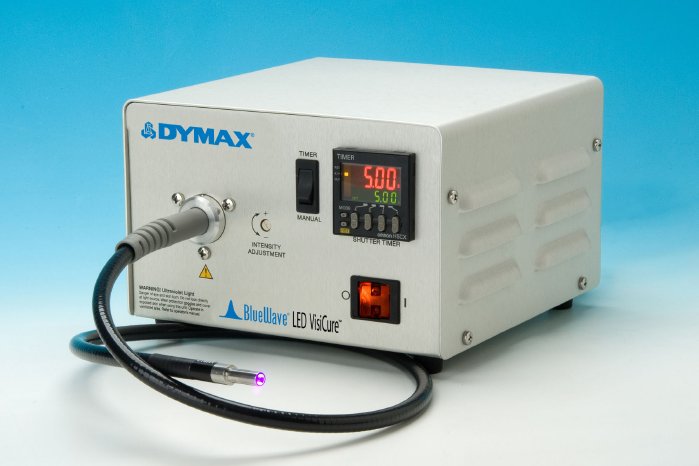

The BlueWave LED VisiCure generates curing energy in a relatively narrow wavelength band centered at 405 nm using high-intensity LEDs and produces nearly double the intensity of any LED spot-curing lamp on the market today. This system delivers maximum curing energy through a 5 mm diameter lightguide, with an output of over 15 W/cm2. While providing more power, the design also eliminates safety concerns from the high heat generated by units with end-of-wand LEDs. In addition, the relatively narrow frequency band produced by LEDs generates cooler curing temperatures at the substrate level. The unit also includes an intensity adjustment feature which allows users to adjust and control intensity output from 0% to 100% to assist with process validation and control. Intensity level measurement is easily accomplished with a radiometer.

The BlueWave LED VisiCure is CE certified, RoHS compliant, and offers user-friendly operation. All of these features make the BlueWave LED VisiCure the ideal curing system for manufacturers looking to complement their “green” initiatives.

As the industry leader in LED light-curing technology, Dymax has developed co-optimized adhesives specifically designed to cure with the BlueWave VisiCure system, enabling customers to quickly and confidently convert to LED light-curing systems.