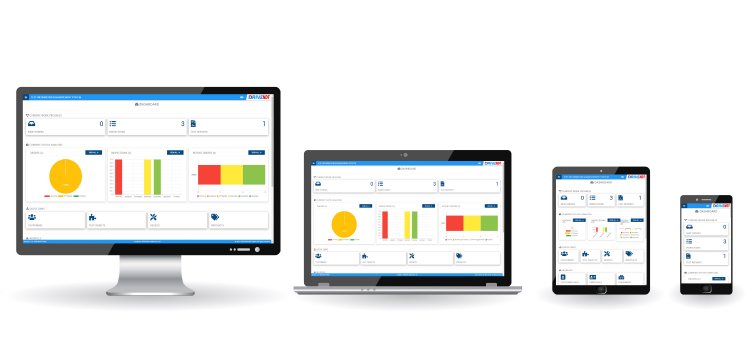

As DRIVE NDT is a web-based application, it can be easily used on any tablet or smartphone allowing users to access it anytime, anywhere, and be constantly up-to-date. A glance at the DRIVE NDT dashboard is all it takes to be completely informed about the current overall status and any upcoming tasks.

With DRIVE NDT, individual test reports for all NDT methods can be easily created and managed. The automatic import of order and test data including from external applications and devices, facilitates order creation and avoids any transcription errors. All test reports can be viewed and edited by authorized inspectors, anytime, anywhere. Every change is logged and the revision status of the report is automatically updated. The integrated revision management and the seamless and transparent process chain ensure comprehensible results and peace of mind during internal and external audits. In addition, end-customers gain confidence in the test results and product quality.

Test objects can be effortlessly set up in DRIVE NDT, for example, pipelines in refineries including their isometry, pressure vessels or turbine blades along with their drawings. A new order can be created from these test objects with just one click; all necessary customer specifications, test instructions, standards etc. are already assigned to the test object and pre-configured. Furthermore, documents of all kinds can be added and managed for inspections and orders in DRIVE NDT, as well as allocated to individual inspections and inspectors.

In addition, DRIVE NDT can be used to easily manage everything related to NDT personnel. For example, the availability of employees and their assignment to orders, as well as management of certificates, radiation doses and medical examination appointments.

Another powerful feature is equipment management which can be used to monitor inspection devices and consumables such as whether a device is available, where it is located, and when the next maintenance or calibration needs to be performed.

Support is provided by automatic system notifications for events related to inspection orders, as well as medical checkups due, recertification of personnel, maintenance of equipment, and process monitoring of workstations. You can also set up appropriate lead times and send additional email notifications which can be extremely helpful in hectic workday situations.

Furthermore, DRIVE NDT has been designed so that it is possible for this data to be evaluated however you like, thus providing an ideal platform to support statistical evaluations such as predictive maintenance.

DRIVE NDT is the key to digitization of the entire NDT workflow and provides unprecedented transparency and, most importantly, enormous increases in efficiency.

www.drive-ndt.com