Especially when parts contaminated with oil are to be cleaned or when subsequent processes such as heat treating, welding, glueing or coating require greaseless surfaces, solvent cleaning can play to its strengths. Thereby cleaning solutions, which reach the required results in a cost effective, process reliable and fast way and which are compliant to VOC guidelines are in demand. Dürr Ecoclean meets these needs of various industrial sectors such as machining as well as manufacturing of stamped, drawn and bent parts with the new EcoCCore.

Reduced costs per unit, optimized application, new design

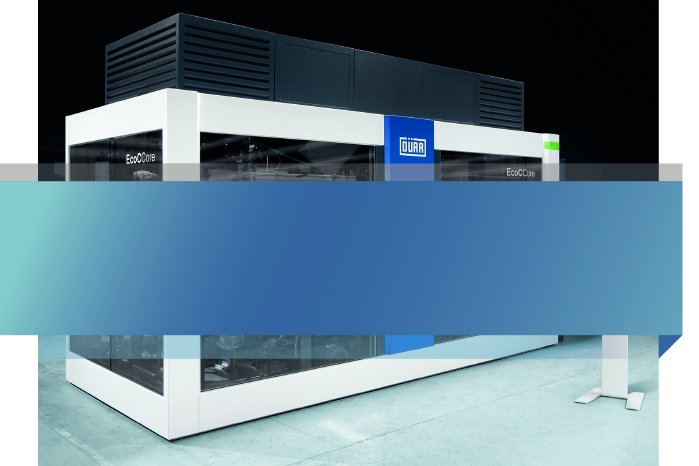

The EcoCCore is developed for the operation with non-halogenated hydrocarbons, modified alcohols and polar solvents. The new system is not only extremely flexible when it comes to the choice of solvent but also when batch sizes are concerned. Engineers especially focused on high process reliability, optimized handling and energy efficiency. The EcoCCore also convinces with comprehensive standard equipment and reduced space requirement.

In addition a noticeable reduction of costs per unit in the cleaning process is achieved. This characteristic enables users to strengthen their competitive position. Besides, the EcoCCore also sets standards in design and transparency of the cleaning process. The new system replaces the current series 81C/P.

It is presented at this year’s parts2clean on the Dürr Ecoclean booth in Hall 4, Stand 4216/4315.

---

Thank you in advance for sending a voucher copy or publication link.

Editorial contact:

SCHULZ. PRESSE. TEXT., Doris Schulz, Journalistin (DJV),

Landhausstrasse 12, 70825 Korntal, Deutschland, Tel +49 711 854085,

ds@pressetextschulz.de, www.schulzpressetext.de