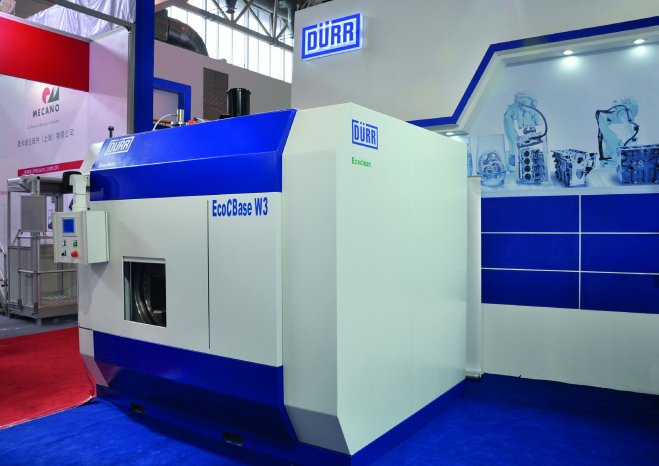

The CMJ Machine-building & Metal-working Awards were presented in the categories of exceptional technological innovation relating to machine tools, cutting tools, testing equipment, lubricants, parts and accessories, as well as for best customer service, high corporate social responsibility and major market influence. Applications had been invited from companies around the world. Among the 40 winning entrants, Dürr Ecoclean was the only manufacturer of cleaning machines.

As a globally active equipment manufacturer, Dürr Ecoclean convinced the experts with its EcoCBase W3, a compact aqueous-based cleaning system. This powerful yet cost-efficient machine distinguishes itself by innovative process features resulting in enhanced cleaning and energy efficiency. One such capability is the choice offered between hot cleaning at 65°C and cold cleaning at around 35°C. Moreover, the standard machine package includes a vacuum dryer which delivers 100% dry parts even after cold cleaning while saving up to 50% energy compared to conventional technology. Thanks to its modular design, the EcoCBase W3 is adaptable to diverse cleaning tasks encountered in the metalworking industry. These range from single-stage processes through intermediate wash and rinse cycles up to sophisticated final cleaning operations involving washing, rinsing and preservation steps.

The award-giving ceremony took place on 13 June in Beijing within the framework of the CIMES trade fair, China International Machine Tool & Tools Exhibition. Of the award winners, 70% were selected by research and academic experts while the remaining 30% were determined through a poll taken among the readers of CMJ Chinamac Journal.

Contact:

Dürr Ecoclean Shanghai

Mr. Markus Reissmann

Phone: +86 (0)21 6250 1178

markus.reissmann@durr-ecoclean.com.cn

Dürr Ecoclean GmbH

Dr. Uwe Schubert

phone.: +49 (0)711 70060

uwe.schubert@ecoclean.durr.com

www.durr-ecoclean.com

Thank you in advance for your voucher copy or publication link.

Editorial contact:

SCHULZ. PRESSE. TEXT., Doris Schulz, Journalistin (DJV),

Martin-Luther-Strasse 39, 70825 Korntal, Deutschland, Fon +49 (0)711 854085,

ds@pressetextschulz.de, www.schulzpressetext.de