Therefore effective management of house dust is indispensable for affected allergy sufferers. According to the remedial action as recommended by medical specialists of an air tight encasing of the mattress and regular washing of blankets and pillows at 60°C, a powerful vacuum cleaner is the best ally in alleviating the affliction. But not all vacuum cleaners are the same. In many commercially available appliances there is a risk that particles, which were collected during vacuuming, can get into the exhaust air and are thereby released into the rooms again.

The premium brand VORWERK sets new standards in the battle against allergy-causing house dust with their innovative Kobold 140 vacuum cleaner - a vacuum cleaner generation which really "swallows" 99.9 of all vacuumed dust. This is ensured by a newly developed, unique filter system. According to the manufacturer, the world-wide first TÜV-certified Premium dust bag for the Kobold 140 produces permanent all-round protection against dust. Michael Weber, Manager of Corporate Communications at VORWERK states: "Up to now, profound cleanliness could only be achieved with multiple, different filters in an appliance. Changing was cumbersome and was sometimes neglected. By replacing the full Premium dust bag with a new one, three filters are replaced in a wink by a single work step. Handy, simple and yet perfectly effective".

The filter technology which was patented seven times, performs three tasks. The pre-filter layer contained in the dust bag initially filters out larger particles. Anti-odour beads in the inner layers of the dust bag absorb bad odours, which could arise in the bag. Finally the HEPA filter retains 99.9% of the allergy-causing household dust. Replacing the old dust bag with a new Premium bag is conceivably simple and clean. The flap of the filter unit is opened, the full dust bag is removed and the new one is inserted. In the process the dust remains where it should be - in the dust bag. The snap-lock closure ensures it is fully sealed. Michael Weber: "Whatever is inside, does not get out again. Therefore even an allergic person can replace the dust bag without coming into contact with the harmful allergen. Incidentally, the exhaust air of the Kobold 140 is 1,000 times cleaner than normal breathable air."

As well as the outstanding filter technology, which makes the Kobold 140 especially suitable for allergy sufferers, the VORWERK engineers have come up with a new design and a new motor for the Kobold 140. Small, with a weight of merely 4kg and very manoeuvrable as a result of the universal joint at the connector of the brush, the new VK 140 gets into every corner. The fully telescopic handle of the appliance, which can completely disappear in the appliance after use, ensures vacuuming without back problems. The Kobold 140 perfectly adapts itself ergonomically to the height of the user and can be stowed away in small cupboards. Convenient recessed grips and a secondary ON/OFF switch on the handle make handling easy.

The new motor of the Kobold 140 is situated in the top of the housing, running pleasantly quiet at 74dB. During vacuuming air is drawn in at the bottom and then passes through the Premium dust bag with its filters, directly into the upper portion of the unit, where it is then exhausted. Thanks to the direct air path the small, low power drive operates highly efficiently: the VK 140 only requires 900W power and yet achieves high power 60,000 rpm. "Dust does not have a chance", says Michael Weber. "In addition the motor is smaller and 45% lighter in comparison to previous models. This is our understanding of innovation." Even animal hair and stubborn fluff is not a problem for the matching Electro-brush 360 of the Kobold 140. This is enabled by rotating bristles and a wide intake opening. Cleaning mattresses at home with the mattress brush saves a trip to a specialised dealer.

Whoever progresses in research and development, does not compromise regarding material and processing. Therefore VORWERK selected a competent full service provider for the production of the Kobold 140, who had to conceptualise the assembly system for screwing down the upper and lower shell of the vacuum cleaner as well as the separate assembly and test unit of the vacuum cleaner. "DEPRAG SCHULZ GMBH & CO." in Amberg, Germany have decades of experience and versatility in the field of screwdriving and feeding technology. Innovative screwdrivers combined with modern, reliable process measurement technology and refined feeding technology make DEPRAG a strong partner in systems engineering. In addition there is the enormous know-how of the DEPRAG engineers. Carsten Hollatz, Purchasing Manager of VORWERK, is full of praise for the systems manufacturer from Germany: "In comparison to system integrators who are obliged to buy in core components, DEPRAG offers all technical solutions in-house." From conceptualisation of the described assembly task, through screwdriving technology, feeding technology and parts handling, as well as control technology and all associated manufacturing processes, the systems manufacturer DEPRAG offers all key technologies from a single source. According to Carsten Hollatz: "This is a big advantage to us, because assembly automation is very service intensive. In case of service requirements, we need a partner who takes overall responsibility and competently assists us".

The assembly system supplied to VORWERK in Wuppertal serves the purpose of screwing down the upper and lower shell of the vacuum cleaner housing, which contains the bellows for the Premium dust bag for filtering the vacuumed air, and the motor. Another, separate machine attaches the cable hook to the hand grip of the Kobold 140, which is already attached to the telescopic handle, and checks preceding manufacturing steps. These two DEPRAG assembly systems contribute towards 1,600 completely assembled Kobold 140 vacuum cleaners leaving the VORWERK factory during a single shift.

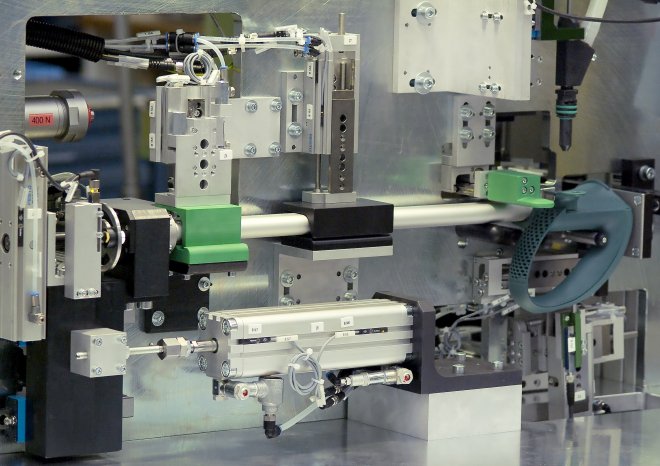

The automated assembly system for the vacuum cleaner housing performs complex assembly and test tasks, which are partly performed successively or simultaneously. Initially the pre-assembled module (upper and lower shell) is automatically transported on a conveyor from the right to the starting position in the assembly unit. A start signal is activated and the assembly process starts. The lifter takes the part, which is now held horizontally by two sliders, from the conveyor. The sliders are furnished with flexible, spring-loaded pins, which accommodate tolerances and distortions of the plastic module. In this way it is ensured that the module is securely held without the risk of being scratched during assembly. A retainer presses the housing into the work piece holder.

Has the module been affixed in the correct position? The assembly system "feels" the correct assembly orientation via the shape of the ribs of the plastic module - only in this way can the subsequent assembly steps be successful. The machine now establishes whether the pre-assembled bellows for the patented Premium dust bag of the Kobold 140 are present by using depth probing. At the same time the air tightness of the bellows is tested with a vacuum test. If the bellows are not air tight, the objectionable module is automatically discharged and is transported to the repair work station, which is integrated in the system.

Presence of the cable hook for coiling the appliance cable is also checked with sensor technology. If these checking processes are successful, the screwdriver spindle is employed. Because of space limitations it is arranged subsurface, i.e. below the work piece holder, and is raised at the start of the screwdriving process. A stationary MINIMAT® angle head control screwdriver spindle, type 377-520-7U-F6.3, turns the switch, which will subsequently control the vacuum power of the unit, anticlockwise to position 3. Important: during subsequent assembly of the telescopic handle, form-fit integration of the handle switch shaft contour and the unit switch actuator is only achieved in this position! The MINIMAT® automatically switches off when 1 Nm has been reached. If it is established during the subsequent test that the required switch position 3 was not reached, the module is discharged to the repair work station.

During the test of the switch position, nine inline MINIMAT®-C screwdriver spindles, type 347C-528-31, simultaneously screw in two different screw types with a torque of 1 Nm: three screws B3.5 x 15.5 mm and six screws B3.5 x 40 mm. The screwdriver spindles are arranged to save space in a very confined area. Checking of the correct torque is done by the strain gauge bar which is integrated into the screwdriver spindle. Dual depth probing, provided for every DEPRAG screwdriver spindle, offers additional process reliability. The housing parts have now been fixed together. If the manufactured parts are not screwed down properly, the defective part is "sent" to the repair work station.

The retainer and screwdriver spindle now return to their starting position and the lifter takes the correctly assembled housing to the conveyor below: the completed vacuum cleaner housing is transported out of the system to the left. During this time the next nine required screws are made available by the standard DEPRAG screw feeding machines, which are integrated into the system. Both and single and dual vibratory spiral conveyors are used. They first separate the screws, which are then "shot" directly into the mouthpiece of the screwdriver spindles through feedhoses.

A repair work station has been integrated into the automated manufacturing process on the conveyor. If the system sends a not OK module for re-working, an employee can decide whether re-working is possible or not. If not, the module is rejected as scrap. Manual re-screwing is checked by integrated sensors: without the re-working step the system does not release the rejected part for subsequent processes.

VORWERK also chose an assembly system from DEPRAG for the assembly of the telescopic handle. A series of test processes has been integrated into manufacturing and serves quality assurance of production, which is top priority at VORWERK. Before the process in the machine is started, an employee manually attaches the cable hook to the vacuum cleaner handle, positions the entire handle in the system and inserts a spring. The slide switch on the handle for controlling the vacuum power is set to position 0.

The important test processes and assembly of the handle now start in the assembly system. The inserted handle is held with various clamping devices in the machine. A total of 17 cylinders are used in the system. They ensure that the module is held securely without being deformed. Tensioning cylinders at the tip of the handle and in the middle ensure reliable positioning of the handle. At the left of the assembly system a stopper holds the handle in its position. This stopper is multi-talented - it will be used later on for tension tests on the handle. A workpiece interlock by means of a second cylinder ensures that the module can only be removed again once all work steps have been completed.

The first test process checks whether the slide switch on the vacuum cleaner handle actually is in position 0 (the completed vacuum cleaner would thereby be switched off). If not, the assembly system stops with an error message and a correction is made. In case of a correct switch position 0, the machine proceeds with the next work step. A test pin slides into the handle and tests the interior of the handle: are the members inside the handle grip positioned correctly, relative to the slide switch? In this way errors from previous assembly processes can be identified and eliminated. The hand grip is only now attached with the handle tube.

A test pin which is moved by a hydraulic cylinder now moves the slide switch on the vacuum cleaner handle from position 0 (vacuum cleaner OFF) to position 3 (maximum vacuum power). The finished, assembled Kobold 140 must leave the factory with this setting - which was also set on the housing. During this work step an additional test is also performed: a check is made, whether the handle is positioned at a pre-defined tilt angle. The system only allows continuation of assembly if this is the case.

Now the pre-assembled cable hook must be screwed to the handle. The required screws are automatically supplied by the Series 5 screw feeding machine, which operates according to the spiral conveyor principle. The cable hook is screwed down with a MINIMAT®-C inline screwdriver spindle to the specified depth. The MINIMAT®-C type 347C-528-31 has a piezo sensor, which at the same time checks the success of the screw assembly by means of depth probing. At the same time the previously applied, correct attachment of the hand grip cap is checked. A test pin on the stopper is extended and pulls against a "nose", provided for this purpose. This tensile test establishes whether the handle tube is attached securely and whether the grip is seated positively.

The cable hook is now turned through 30 degrees, whereby it is ensured that the cable hook is properly attached for subsequent packaging. At the end of the assembly process there is a hot embossing process, which furnishes every module with a manufacturing identification number. In this way it can be traced within quality management, according to which manufacturing status the telescopic handle was assembled.

VORWERK & Co. KG is a family enterprise founded in 1883, with headquarters in Wuppertal. The core business of the company, which evolved from a former carpet factory, is the world-wide direct sales of high quality products. The Kobold business sector represents 31% of turnover and offers solutions in the premium segment with the hand-held Kobold vacuum cleaners and with the Tiger floor vacuum cleaners. In 2009 VORWERK achieved a turnover of 695 million Euro in the Kobold business sector. The primary markets are Italy, Germany and China.