DEPRAG SCHULZ GmbH & Co., based in Amberg, Germany, is an international supplier for quality air motors, automation, screwdriving technology and air tools to major conglomerates and industries. The company has decades of experience in processing steel as a raw material. Professionals in special heat treatment procedures, DEPRAG provides heat treating service for their own production, as well as external clients.

Before being assembled into one of DEPRAG's quality air vane motors the steel rotor must undergo heat treatment. DEPRAG employs a combined process, known as case hardening. This method is primarily used for high wear gear components, shafts, special purpose tooling and other machine parts made from low carbon steel.

The principle of air motors is simple. Compressed air sets the rotor in motion within an eccentric cylinder. There are vanes within its slots which are pushed outwards against the edge of the cylinder wall by centrifugal force. Working chambers are formed for the compressed air. The expansion of compressed air transforms pressure energy into kinetic energy and the rotational movement is generated.

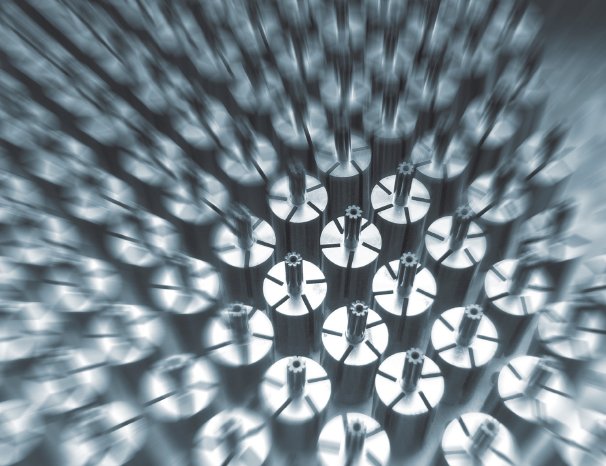

Air vane motors require a highly resilient rotor for a long lifespan. Rotors are turned, milled and toothed in a workholding system on modern bar automatic lathes. After hardening, the rotors are processed to their final tolerance dimensions on highly accurate grinding machines. The slots for DEPRAG vanes are created on a production machine which was specially designed for DEPRAG and guarantees top quality durable vanes.

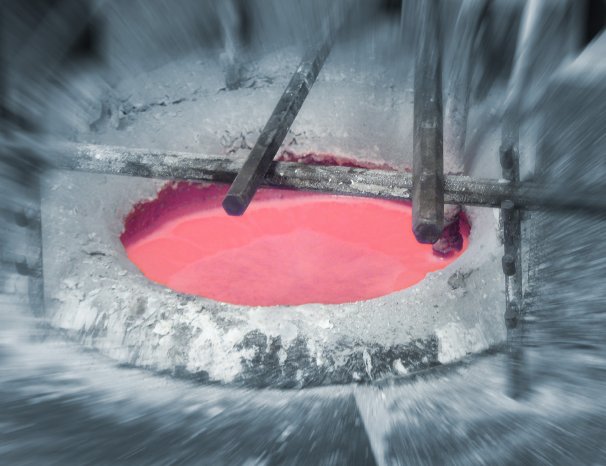

As a prerequisite to the next step in the case hardening process, the steel rotor is immersed in a salt bath at temperatures of up to 950 degrees and held there over a certain time period. The surface layer of the steel is enriched with carbon through diffusion (carburized). The carbon content in a salt bath is particularly well regulated and therefore the results of this process on the work piece are very consistent. The usual case depth, depending on the component and customer specification, is between 00.5 and 1.5 millimetres.

After enrichment with carbon, the steel rotor is hardened and then tempered (relaxed). During hardening the steel is heated to the austenite phase (over 723 degrees Celsius) and then quickly cooled (quenched) in order to circumvent the pearlite and ferrite phases and reach the so-called hardened martensite microstructure. The hardening procedure is followed by tempering (regulated reheating) process in order to give the steel back a certain degree of strength and ductility.

Salt bath heat treatment increases the mechanical characteristics of steel. Results are: increased rigidity of the component, wear resistance is heightened due to the surface hardening, core ductility is magnified, the load capacity is boosted and resilience toward alternating flexural stress and overload tolerance are improved. Salt bath hardening is recommended for the treatment of components used in precision engineering, tooling for applications in extreme heat and cold conditions and other highly stressed machine components, for example; the rotors on air vane motors.

A special treatment after the hardening process is tempering. Tempering involves the regulated reheating of the material to high temperatures (up to 700 degrees Celsius). The aim of this process is to give the steel/alloy the highest possible strength and at the same time increased ductility. Machine components which are subject to sudden loads and safety components which must withstand large distortions are recommended as candidates for this technique.

Annealing is an additional heat treatment technique wherein more emphasis is applied to a controlled cooling phase. It is specifically used to induce material properties generally associated with the softening and stress-relief of internal material structures thereby improving the ductility and cold-working properties. Annealing is also included in the spectrum of applied technologies at DEPRAG.

DEPRAG's production location in Láznê Bêlohrad in the Czech Republic offers economical and extremely reliable gas hardening for larger production batches in their gas hardening facility.

Distortion-free hardening of materials is almost impossible because of the alterations to the microstructure of steel. However, through decades of experience, the DEPRAG team is in a position to reduce the distortion to its absolute minimum. DEPRAG's heat treatment technique is certified according to the standard DIN EN ISO 9001 and is subject to strict quality controls appropriate to each application and situation. The components receive a quality certificate after standing up to the Rockwell, Brinell and Vickers hardness tests. Either a digital or printed image displays the steel microstructure or the case depth from under the microscope. This is a destructive test and is used primarily for spot tests on large production batches.

Extensive consultation and advice in the correct choice of material, heat treatment techniques and the proper observance of hardening regulations are included in the range of material treatment services provided in Amberg. The service also covers metallographic examinations and damage analysis. All normal heat treatable steels, and also in small quantities, highly-chrome-alloyed steel components with a maximum breadth of 280 millimetres and maximum length of 450 millimetres can be processed in the DEPRAG heat treatment facility up to 1300 degrees Celsius. The specialists at DEPRAG know that great importance is attached to flexibility and short reaction times and therefore process their customer's orders accordingly.