The existing product range of thermal printers has been expanded to include three further models in the upper speed range. The devices excel through simple operation and administration using the "Easy System". Besides the direct thermal printer 7106, there are the two thermal transfer printers 7206 and 7010, which offer automatic ribbon tension, making for excellent printing results. What all these products have in common is a sturdy, all-metal print mechanism, which means that even large print orders in an industrial environment can be processed without any problems.

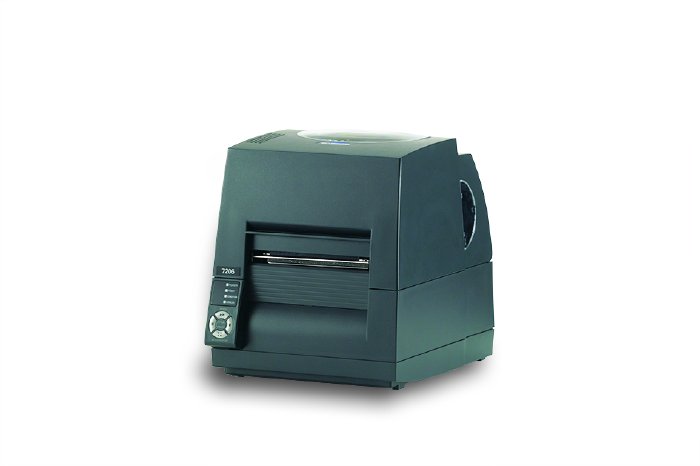

Direct thermal printer 7106 and thermal transfer printer 7206 have a printing width of 104 mm and work at a speed of up to 152 mm per second. Both devices can be adjusted to the particular customer requirements with a number of options, such as dispensers, cutters and large paper roll holders.

The flagship of the new product series is thermal transfer printer 7010, which is impressive with its sturdy and elegant housing. All the settings can be input directly via a display panel, and inserting the print material is also a quick operation thanks to the housing opening upwards, which also makes for a small footprint. The basic machine can also be upgraded with dispensers and cutters, and with model 7010R there is a version with integral winder available. Both models achieve a printing speed of up to 254 mm/second.

"With the new models, we are transferring our renowned attributes of 'robustness', 'reliability' and 'efficiency' from the dot matrix printers to the thermal printers," says Michael Ried, Marketing Manager at DASCOM Europe. "These printers reflect the wealth of experience we have in this customer segment. For this reason, we offer a unique 3-year manufacturer's guarantee for our thermal printers at no extra cost."

The printers are available in the specialist trade as from now. You can find further information on the new models and other print solutions from DASCOM at www.dascom.com.