Kamensk Uralsky Metallurgical Works is one of the largest downstream companies in Russia. KUMZ has a rich history as it was founded in 1944 as a manufacturer of semi-finished products in aluminium-, magnesium-based and aluminium-lithium alloys. Today they supply high quality aluminium plates, wide variety of extruded products (rods & bars, profiles of different shapes & wide railway extruded panels as well as aluminium tubes & drill pipes). KUMZ is also specialized in forged materials supplying die-forgings, hand-forgings, rolled rings, forged plates and bars to aerospace, military and automotive industries. KUMZ three productions are situated in one place.

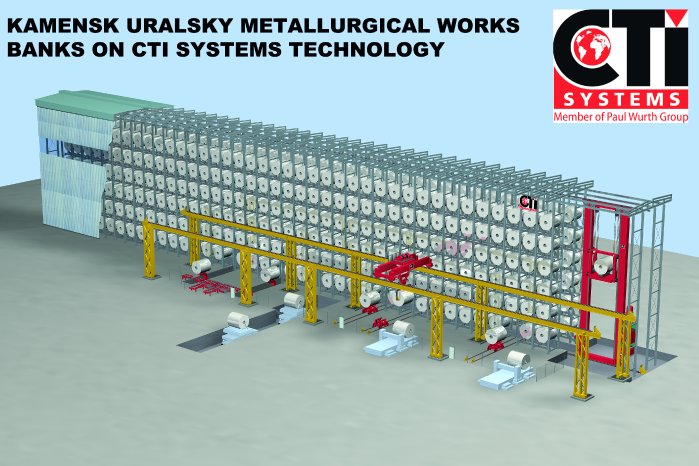

The order that CTI Systems has received from KUMZ consists in the design, manufacturing and installation of their first fully automatic high bay warehouse for coils including all periphery equipments and ventilation system.

KUMZ which is one of the world’s top ten aluminium producers of high quality semi-fabricated product in aluminium in Russia for worldwide market, has start the second phase of project to build a new milling facility. Part of its investment program is aimed at enhancing materials handling functions after the hot rolling shop which processes hot aluminium coils.

The complete installation consists of a central warehouse incl. stacker crane, automatic cranes and floor carriers as input/output device.