That should never be the answer.

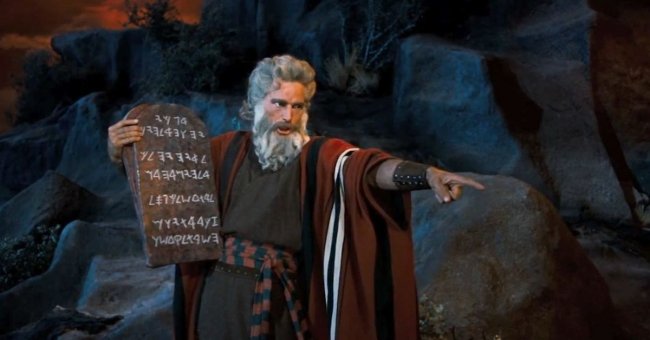

There are certain guidelines that any software supplier should follow when deploying a new system to a shop floor. Here are the 10 Commandments for the Software to Human interface:

Commandment #1

The same information should never be entered more than once. [Once captured, the system should store it and retrieve it when needed. Never have a human enter it twice. This is time consuming, wasteful and simply introduces the possibility of a deviation should the two values not match.]

Commandment #2

Never ask a human to perform an action that could have been captured by a machine or implied by a process.

Commandment #3

Avoid free format fields on screens. [Always provide a list of choices if possible or at a minimum some formatting or limits to control and verify information as it is entered.]

Commandment #4

It is better to filter information on the way in than to verify it after it was entered.

Commandment #5

Never ask a person to enter something that the system should already know.

Commandment #6

Keep it simple. A screen should have one purpose and that purpose should be clear and unambiguous.

Commandment #7

Do not have secret fields, hidden commands or back doors. Screens should be open and honest. [An exception to this rule would be features added just to make the system interesting… see Commandment #10.]

Commandment #8

Use scanning devices to capture the identity of what you are processing whenever you can. [These can be bar-code, RFID or telepathy but whenever possible, eliminate typing.]

Commandment #9

Never impose a process on the human just because the tracking system needs to do it. [Fix the tracking system to live with the information that the factory provides as a standard part of its processing. If that doesn’t seem like enough to get the job done, then think of better ways to get what you need.]

Commandment #10

Make it interesting. [When people are more involved in something and the more they are engaged, the fewer mistakes they make. Add some color, change out the messages, and make the person using the system gain some personal value from it and you will have fewer problems.]

Help make a happy factory.

The following article was published on the 5th of May 2016 on LinkedIn Pulse

Posted by: Steve Rolston, Medical Device MES Expert, Critical Manufacturing