But is just creating electronic records of shop-floor events enough or is there more that the MES has to offer compliance wise?

Today we will try and determine how the MES application with a centralized QMS facilitates complete compliance, i.e. how the MES influences all aspects of compliance and meets even the most detailed requirements to keep the compliance endeavor perfect!

IT ALL STARTS WITH CAPTURING THE SHOP-FLOOR DATA.

The MES, when it's able to capture necessary information at the right instant, allows compliance to become a more entrenched and well-practiced activity, not deterred by any human error or unnecessary delay due to the said manual efforts. It also makes the activity more accurate, automated and elaborate as it is carried out always as prescribed and in the back-ground, allowing the actual workforce to concentrate on meeting the standards without worrying about recording and reporting them. But this is just the tip of the iceberg; the MES goes far beyond recording and maintaining records for compliance.

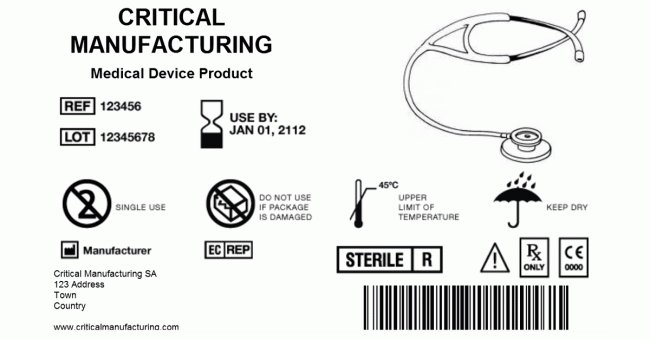

The regulatory bodies such as the FDA, prescribe many rules for the manufacturers to follow, such as how the process should be executed, to how much percentage of an additive or ingredient should be used, to how many people should perform/supervise an activity or process, what kind and composition of labels to be applied to a particular product, and many more.

The MES to this end is fully capable of meeting all regulatory requirements, if used properly and designed to do so! Where the matter of proper training to handle a piece of equipment or a critical part of the process is concerned, the MES has the capability of confirming that whether or not an operator or supervisor is trained to handle the activity or machine. Not only that, the application can also alert personnel that they need to renew their certificate of there has been an update in the certification requirement. This allows relevant personnel to be fully prepared and also completely prevents non-qualified personnel from performing an activity or handling a piece of equipment they shouldn't.

For more information about Complete Compliance click here to read the complete blog post http://goo.gl/tfdnOF