Posted by: João Cortez, Product Manager, Critical Manufacturing

Selecting the right MES is a very daunting task. Unlike ERPs which handle well established corporate processes and for which the number of vendors is relatively small, Manufacturing Execution Systems (MES) address a variety of industries and manufacturing processes and the number of vendors is very high. As the MES is a critical application at the heart of the organization manufacturing processes that requires a considerable budget, time and effort for deployment, a hit or miss in the MES selection will have a significant impact in the competitiveness of the company.

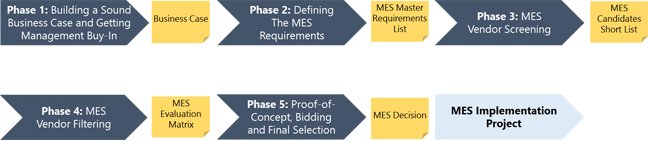

In addition, once an MES is selected, the company will be for locked-in into the solution for a large number of years. Therefore, the MES selection should be treated as a high-importance project of its own and it must follow a sound process that maximizes the probability of coming to the right MES selection. This post describes a recommended MES selection process that is designed to be effective and to minimize risk and that can be adjusted according the specific MES evaluation context.

(see attached image of selection process)

Phase 1: Building a Sound Business Case and Getting Management Buy-In

Before embarking on a MES selection project, the company must establish a sound business case. That will provide the buy-in and support from the relevant stakeholders, secure the necessary funding, and it will set and align the project expectations by providing the boundary conditions in terms of time, scope and budget for the MES project implementation.

Phase 2: Defining The MES Requirements

The first part of any project is to define the requirements. Requirements are of three types:

- Functional – which functions must be provided by the MES application

- Technical – which technical requirements (e.g.: technology, obsolescence risk, integration capabilities, scalability, availability, latency, extensibility, user interface ergonomics) must be fulfilled by the MES application

- Business – other requirements related business aspects such as the vendor size, geographical presence and financial situation; product references and roadmap; training, documentation and support; and other contractual related requirements

Phase 3: MES Vendor Screening

Once the requirements are known, and since it’s simply not practical to analyze every single possible MES vendor, it’s necessary to create a short list of MES vendors to be considered. Based on the list of requirements, and using a combination of Internet search, expert’s consultancy, and market research (such as the one from Logica/CGI), the project manager must come up with a list of four-to-six potential MES candidates. This list must be presented to the steering committee for validation.

Phase 4: MES Vendor Filtering

The next step is to narrow the list down from four-to-six potential MES candidates to two. A good process is to prepare an evaluation matrix with different weights based on the list of requirements. There are some key activities that must support the fulfillment of the evaluation matrix and the vendor filtering: a vendor questionnaire; a product demo; and whenever possible, a tour at a vendor reference site. The vendor questionnaire is based on the list of requirements and is submitted to the vendor. The product demo is requested to the vendor, and in addition to the general product demonstration, be sure to request the demonstration of key complex scenarios. It’s a good idea to see the product in action at a live production site, so ask the vendor for the opportunity to visit (on site or remotely) one reference installation site and to talk directly with the reference customer. Have the different stakeholders to fulfill the evaluation matrix values for each vendor and consolidate them at the end in order to come to a final result. The top two candidates, after validation of the steering committee, are then selected for the next phase.

Phase 5: Proof-of-Concept, Bidding and Final Selection

In this phase, there must be a proof-of-concept for each of the two candidates. Each candidate must install the product locally at the company site and carry out a more extensive demonstration of different scenarios. The key users must also have the chance to get hands-on experience with the product. At the same time, the details of the contract agreement must be worked out. The evaluation matrix developed in the MES Vendor Filtering Phase must be supplemented with additional information that reflects the degree of fulfillment and quality of the proof-of-concept as well as with additional contractual information (namely the price and the timeline).

Here again, it’s important to consider the input from the different stakeholders. Also, if during this phase new information is discovered, the evaluation matrix results of the MES Vendor Filtering Phase need to be updated. If there are open questions that are relevant for the final decision, they need to be cleared at this stage. The steering committee must then consider the new evaluation matrix and all information gathered so far to make the decision on the final selection. After capturing the decision results and the decision rationale, make sure to congratulate the team. It’s time then for the MES project implementation.