CoreTigo’s wireless technology ensures high reliability (6 orders of magnitude more reliable than other conventional wireless technologies), low latency (5 msec.), a synchronized system (based on IEEE 1588) and deterministic behavior fit for factory automation control applications. As an example, cabling limits the motion and flexibility of robots/cobots. The end effectors (e.g. grippers, vacuum pumps) attached to robots/cobots require communication cabling and are cumbersome to deploy. CoreTigo’s wireless solution embedded inside the end effector eliminates the cables and accessories required to run all along the robotic arm, thus increasing flexibility and reducing overall complexity and cost. CoreTigo and Zimmer Group have jointly developed such an IO-Link Wireless Gripper solution on a collaborative robot which has recently won the German Innovation Award. CoreTigo and Schmalz GmbH are also developing IO-Link Wireless solutions for vacuum pumps that can be wirelessly controlled on robots or cobots.

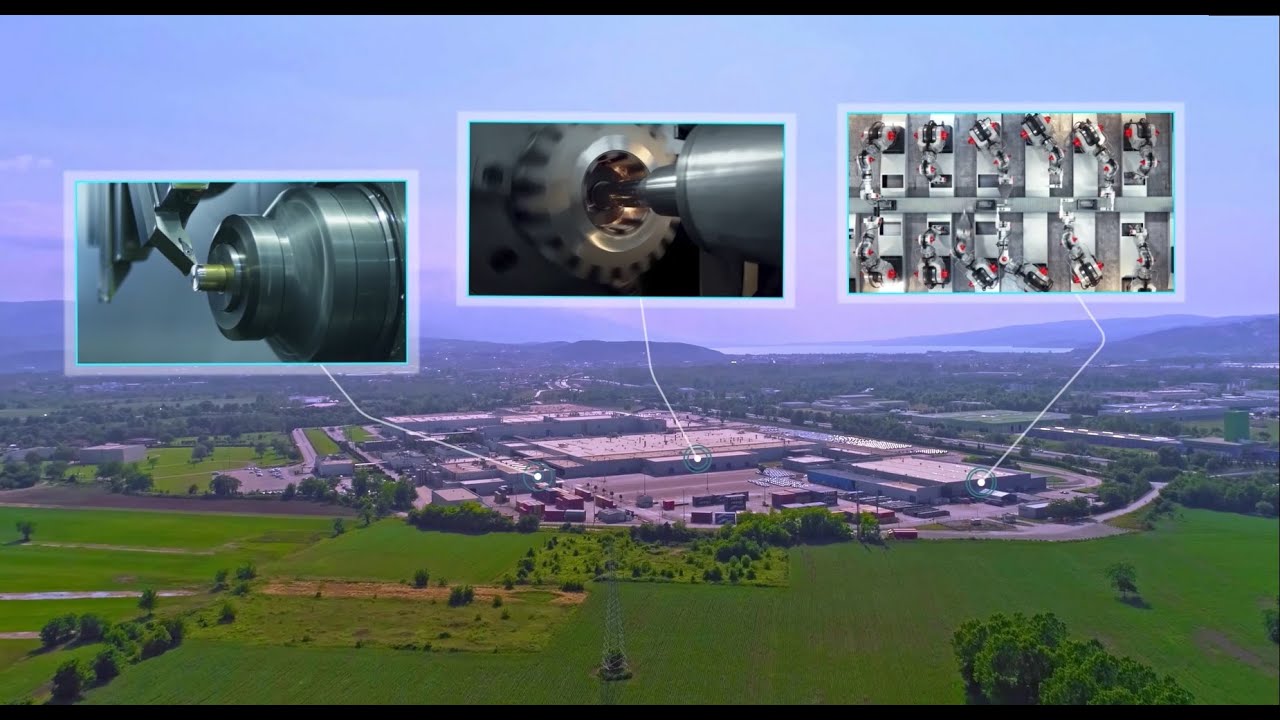

Additional solutions include CNC, welding, milling & grinding machines which require constant data feedback while rotating, moving and cutting at high speeds in harsh environments with extreme conditions. Cable communication and other conventional wireless technologies are not feasible for such sensitive and critical data collection. An industrial wireless solution enables ongoing data collection to enable predictive maintenance, data analysis, product quality improvement and machine optimization. View the following video to see CoreTigo’s wireless solutions.

The TigoAir SOM (System on Module), TigoAir LP SOM, and TigoBridge SOM are CoreTigo’s IO-Link modules for designing and building these IO-Link Wireless sensors, actuators and I/O hubs. CoreTigo’s IO-Link Wireless devices can be configured and set up via the TigoEngine IO-Link Wireless network management tool. A variety of applications for data visualization, analytics and monitoring can also be built with the TigoInsights software platform. To learn more about CoreTigo’s products and solutions, please visit CoreTigo’s Website.