ContiTech carries the climateneutral printing blankets in its CONTI-AIR® HC lineup under the PURE PRINTING label and in its PHOENIX Xtra BLANKETS CARAT series under the CLIMATE-Xtra-BLANKETS label. "Our products are to be found wherever industry is looking for overall solutions of an ecofriendly quality," notes Heinz-Gerhard Wente, chairman of the Executive Board of ContiTech AG. "Our driving concern is always to contribute to enhancing the quality of life and environmental protection. We're involved where the future's in the making - which means especially in the printing industry, too, with climateneutral printing blankets."

"By assuming a climateneutral stance, ContiTech Elastomer Coatings has bolstered its leadership position in the printing blanket domain in terms of innovative environment and climate protection solutions," adds Heiko Eymer, head of the Elastomer Coatings business unit. "We are proud to be the world's first manufacturer marketing climateneutral printing blankets and thus able, in this major way, to contribute to environmentally sound printing. And this is achieved at no extra cost to our customers."

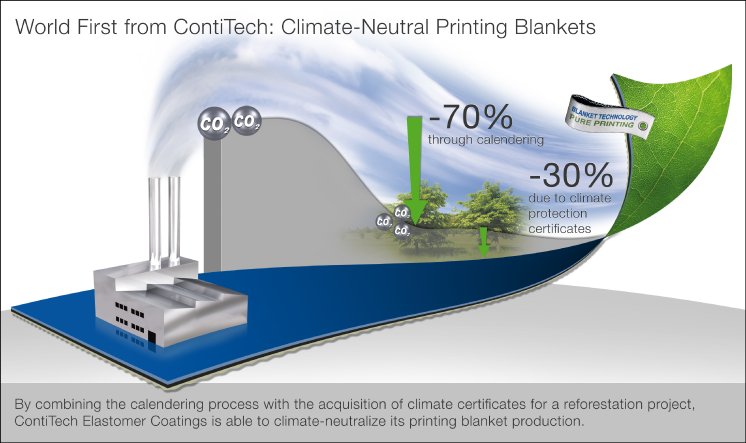

Enhanced climate protection thanks to calendering technology

The calendering process used in making CONTI-AIR® HC line and PHOENIX Xtra BLANKETS CARAT series printing blankets is chiefly responsible for the small carbon footprint. A steel roller forms the rubber into a slab of the requisite thickness. This is a much more energyefficient approach than the conventional coating process. What is more, solvent additives can be dispensed with, so VOC (volatile organic compound) emissions are greatly reduced.

The calendering process's favorable carbon footprint was determined last summer. ContiTech Elastomer Coatings was the world's first manufacturer to have a life cycle assessment of its printing blankets drawn up and then certified, in this case by Ostwestfalen-Lippe University of Applied Sciences under the direction of Dr. Manfred Sietz, professor, und Martin Komander, graduate engineer. Compared to the conventional manufacturing process for world standard printing blankets, 70 percent fewer CO2 emissions were found to be released in producing printing blankets in the CONTI-AIR® HC lineup and 35 percent fewer for the PHOENIX Xtra BLANKETS CARAT series. In the upcoming months the production sequence for the CARAT series will be further optimized, resulting in an additional reduction in CO2 emissions.

"As good as these values already are, we are going a step farther, because we want to offer our customers climateneutral printing blankets," explains Perkovi?, head of the printing blanket segment at ContiTech Elastomer Coatings. "That is why we opted to acquire climate protection certificates as a means of neutralizing the remaining CO2 emissions."

Keeping things eco- and climatefriendly is one of the main challenges facing the printing industry. Solutions are in the works in all areas of production, materials and processing to render printed products more environmentally compatible and climatefriendly. As Perkovi? emphasizes: "We combine the calendering process with the acquisition of climate protection certificates because we want to help our customers achieve this goal. This puts us well ahead of all other printing blanket manufacturers."

Reforestation project in Panama

To neutralize the remaining CO2 emissions, ContiTech acquired climate certificates from natureOffice (www.natureoffice.com), a climate protection agency. In so doing, ContiTech supports a reforestation project in Panama that benefits not only nature but also those living in an economically underdeveloped region. Planting trees creates a tropical forest that pulls carbon dioxide out of the atmosphere and releases oxygen. At the same time it protects the groundwater, prevents soil erosion and offers a habitat for rare fauna and flora. Longterm jobs with social benefits are, moreover, also created for the people in the area and their lives improved, not least of all by making microloans available to them.