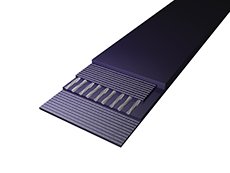

Elastic steel cord conveyor belt for small-radius bends

TransCord represents a new level of development in the realm of steel cord conveyor belts. The conveyor belt combines the properties of both steel cord and fabric belts and thus opens the door to an even broader range of applications. It is, for example, much more flexible than conventional steel cord conveyor belts, making it suitable for use on lines with much smaller curve radii. "Elastic cords are used for the TransCord. That means it is not as longitudinally stable as conventional steel cord conveyor belts," says Kantorek. The new TransCord conveyor belts can also be used in systems with relatively small pulley diameters. On such systems, other steel cord conveyor belts of the same strength quickly run up against their limits. The TransCord needs shy away from comparison with conventional fabric belts, either; on the contrary, it performs much better than fabric belts in terms of material impact and its stretch behavior is also superior. Conventional cords are used for the carcass, as are cords with more stretch. The hard rubber compounds on the cords ensure very good bonding of rubber and metal. "We manufacture the belt using a procedure that is actually more in line with manufacturing fabric belts," says Kantorek. "Nevertheless, TransCord is a genuine steel cord conveyor belt." All TransCord conveyor belts can be produced using the most varied of cover stock materials

(normal qualities, ultra wear-resistant, temperature-resistant, flame resistant, partially oil- and grease-resistant).

Low stretch behavior proven in practice

A further innovative product solution by ContiTech are the EPP textile conveyor belts CON-MONTEX® and CON-BITEX®. Thanks to a special fabric consisting of straight chaining and filling threads, they are particularly robust. The EEP belts feature a compound carrier made of polyamide (P) between the transverse and vertical threads. "The fabric used for the EPP belt is just as strong as an EP belt, yet 15 to 20 percent lighter," says Kantorek. Furthermore, both belts are characterized by optimal running and troughing properties and extremely low stretch behavior, which has proven itself in day-to-day use in cement plants, for example. In this application area, EPP belts prove to require much less maintenance than conventional steel cord conveyor belts. It is much easier to take care of any maintenance and repair work - an important factor for cement plants.

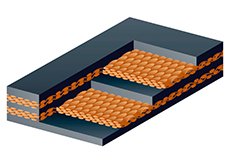

Setting the trend in the area of steep conveying

ContiTech relies on trend-setting innovations in the area of steep and vertical conveying. These innovations include FLEXOWELL® conveyor belts that are designed for horizontal, steep-angle, and vertical transport of bulk materials of all kinds - from coarse coal and ore, rock, granular sand or fertilizer to grain. The particle size can vary from ultra-fine, floury matter to chunks up to 400 mm thick. Capacities of up to 6,000 metric tons per hour and lifting heights of up to 250 m are possible. The benefits for system operators include quick installation, fewer material transfer stations, long service life, reduced energy consumption, and eco-friendly handling. POCKETLIFT® is the only continuous conveyor system for stroke heights of up to 700 m and capacities of up to 6,000 t/h. The conveyor belts are a further-advanced version of the successful FLEXOWELL® technology; they are only used vertically, however. "Power transmission is achieved with the help of two narrow steel cord conveyor belts that are connected with stable triangle-shaped cross members," says application engineer Benedikt Nothelle, head of sales at the Conveyor Belt Group. The material transported is carried in fabric-reinforced rubber pouches. The pouches have a carrying capacity of up to 4,000 m³/h. Thanks to these characteristics, POCKETLIFT® numbers among the trend-setting solutions for steep and vertical conveying.