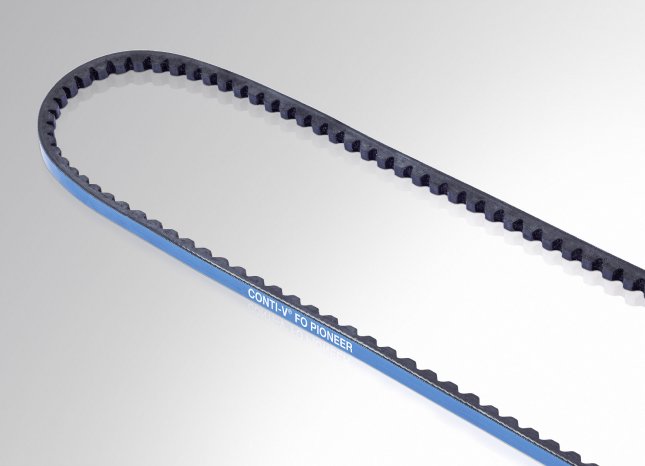

- Raw-edge V-belt on basis of ethylene propylene diene monomer rubber (EPDM)

- FO Pioneer provides improved product properties compared to the FO Advance

Growth for the drive belt range: With the FO Pioneer, the ContiTech Power Transmission Group introduces a high performance raw-edge V-belt for drive solutions in machine and plant engineering. Compared to the FO Advance, the FO Pioneer offers up to 20 percent more power transmission and longer service life - a development that demonstrates the extensive material expertise of the specialist in rubber and plastics technology.

The raw-edge drive belt is oriented towards the needs of the industry. It owes its improved product properties to its base material ethylene propylene diene monomer rubber. "EPDM has numerous advantages over conventional rubber compounds," explains Regina Arning, Head of the industry segment at the ContiTech Power Transmission Group. "The material is dynamically more stable and has a higher temperature resistance ranging from -40 °C to + 120 °C."

A sub-construction made of EPDM forms the basis, a tensile member made of polyester and a cotton cover provide more stability. The new belt is resistant to dust and tropical conditions, it is also conductive according to ISO 1813 as well as partially oil resistant. It will be available in the fourth quarter of 2015 and will replace the FO Advance in dimensions up to 2,932 mm. "Our customers benefit from a consistent development, whereas the price level remains the same," says Arning. For applications that require belt lengths over 2,932 mm, ContiTech continues to offer the V-belt FO Advance.

More Information:

ContiTech Drive Belts for Industrial Applications