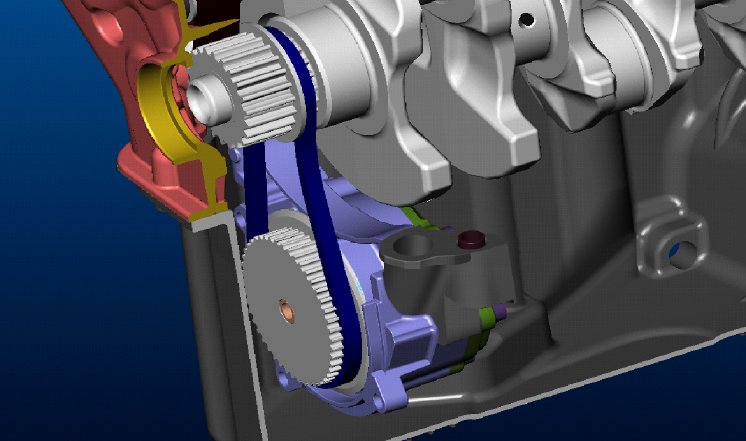

- High-tech belt for driving oil pumps and camshaft timing assemblies

- Reliable transfer of drive forces in oil environments at extreme temperatures

- Reduction of fuel consumption and pollutant emissions

- Initial use planned in 4 cylinder engines

CONTI® OIL RUNNER is one of the innovative products ContiTech Power Transmission Group is aiming to use to capture new markets for the future. Thanks to its fiber-reinforced HNBR compound and special tensile member, the timing belt also transfers drive forces safely and reliably in oil environments at extreme temperatures. The timing belt is therefore a perfect solution for driving oil pumps or camshaft timing assemblies - and scores well in a comparison with timing chains. Benefits these high-tech belts enjoy over their metal counterparts include reduced friction loss, improved noise levels and much slighter lengthening of the belt. Series production release is currently underway for a major automobile manufacturer. "We are reckoning with the series approval some time this year," says Hermann Schulte, head of timing belts development at ContiTech.

Initially, this innovative belt is to use its strengths to drive oil pumps in 4 cylinder engines. In the same amount of space required by a steel chain, the belt reliably drives the oil pumps in oil environments at temperatures exceeding 120°C - for the entire service life of the engine. To meet these demanding requirements, the CONTI® OIL RUNNER comprises only the best components. Its fiber-reinforced HNBR compound does not swell in oil and enables extremely high application temperatures, while it also incorporates an innovative tensile member made of glass fiber, the special design of which, in combination with a new type of coating, offers excellent media resistance. This also ensures good protection against belt tears, even after the belt has been in operation a long time.

When a dual pulley drive is equipped with a CONTI® OIL RUNNER, no tensioner is required so the system can be offered at a significantly lower cost than a chain drive. In camshaft drives, the belt is also eco-friendly, reducing the vehicle's fuel consumption and improving emissions characteristics while its optimized noise characteristics enhance driving comfort for the driver too. Automobile manufacturers therefore rely on timing belts rather than chains ever more often when designing economical, eco-friendly, climate-compatible engines. This benefits car drivers too since, as of July 2009, car taxes for new vehicles in Germany are determined in part based upon their CO2 emissions. The European Union is also planning fines for vehicle manufacturers if CO2 emissions exceed a legally permissible level from 2010 onwards.