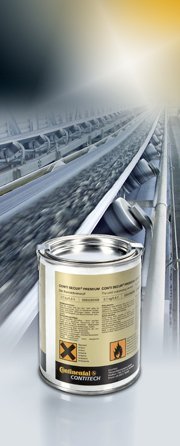

For users, the one-component adhesive based on polychloroprene offers two main advantages - firstly in terms of metering, secondly in terms of application and handling. As there is no need for a reinforcement solution, there is no risk of mistakes being made during metering. Furthermore, every last drop of Conti Secur® PREMIUM can be used, without the adhesive vulcanizing in the container within a short space of time, which makes the adhesive particularly cost-effective. Conti Secur® PREMIUM can be used in a range of different applications, including rubber-to-rubber bonds and rubber-to-metal bondings, as well as for cold splicing of fabric ply belts.

Another advantage over two-component adhesives is the reduced packaging volume thanks to the omission of reinforcement solution. This reduces costs both during dispatch and in storage, not to mention during waste disposal.