Power unit mounts are the key connecting element between the engine, transmission and body. They include engine and transmission mounts and pendulum and torque reaction mounts. They are designed to secure the assembly in the engine compartment and mount it such that it does not come into contact with the body, and does not become detached even under extreme loads - for instance in an accident. The mounts also cushion impacts due to uneven road surfaces and absorb vibrations.

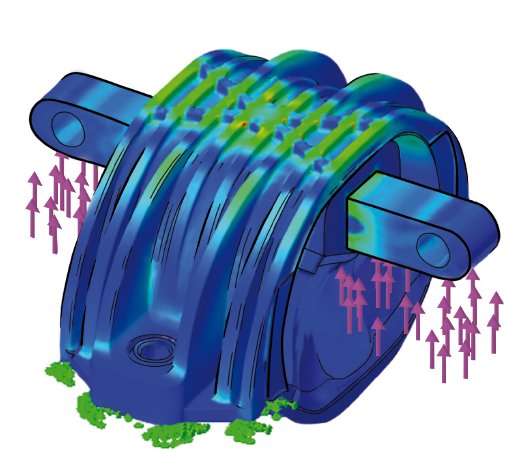

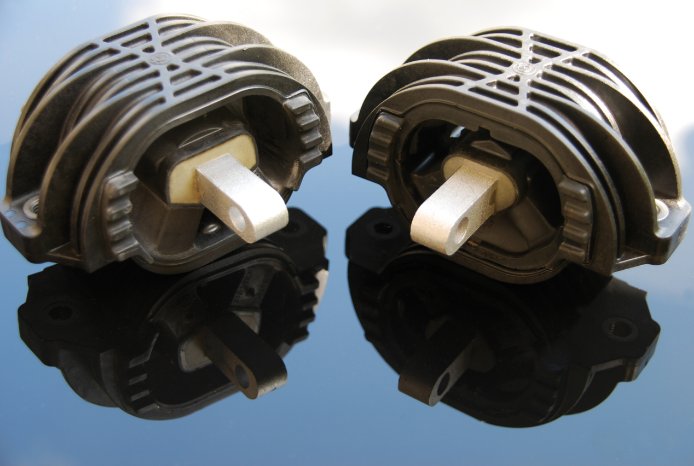

Such loadbearing structural components are primarily made from steel or aluminum. The heavy weight not only affects the vehicle mass and thus the fuel consumption, but also the axle load distribution. Particularly for vehicles with laterally mounted engines and frontwheel drive, the load on the front axle is large which can reduce safety and restrict driving dynamics. With their power unit mounts made of fiberglassreinforced polyamide and perfectly designed for such loads, ContiTech Vibration Control has developed a innovative product ready for the market. This development was the result of intensive calculations and extensive lab and vehicle tests. In addition to selecting a suitable material, it was important to use this material as sparingly as possible. Areas exposed to high loads are optimally designed and the material properties are best utilized by defining the general conditions of the production process. The results of multiple tests have shown that the mounts meet all the requirements and weigh not one gram more than necessary.

In current GM models such as the Opel Insignia this new standard of technology is being applied as in luxury class cars. A transmission mount from ContiTech is a standard component in the BMW 740i and 750i and is to be used in other BMW midrange and luxury vehicle types. In this way, Conti-Tech supports the automobile industry in producing lighter vehicles that stand out from the rest with their low CO2 emissions. The innovative mounts weigh up to 50% less.

Moreover, since plastic can be shaped at temperatures much lower than required for aluminum, the production process requires much less energy. Even logistics is minimized. Normally, mount manufacturers on the global market obtain metallic components from specialized production plants (e.g. foundries). This means that materials are transported over very long distances. However, the new power unit mounts from ContiTech are produced onsite in Hanover in a highly automated series production process. This reduces logistics and storage costs enormously.